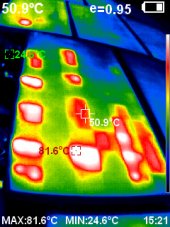

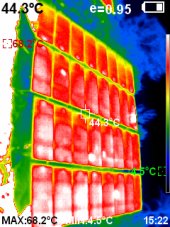

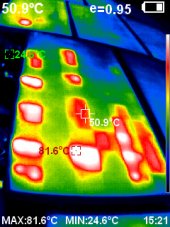

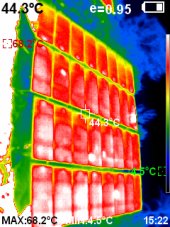

The array being tested.

Originally 9s2p installed around 2004 or 2005, now 12s2p with the column of 6 panels on the left acquired later.

These Sharp NE-Q5E2U panels are paralleled with 24s AstroPower AP120 into one Sunny Boy 5000US GT PV inverter. One one occasion, inverter reported 357 Vmp, Astropower delivered 3.71A Isc, Sharp (panels on left of array) delivered 3.20A Isc, Sharp (panels on right of array) delivered 2.17A Isc.

View attachment 63329

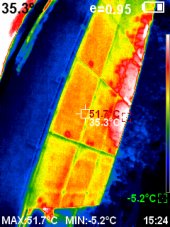

Tester, measuring Rload. Voltmeter (here set to ohms) is across MC cables for PV input.

Heavy-duty knife switch connects PV to power strip with oil-filled radiators as load.

General-duty knife switch shorts for Isc.

The heavy-duty switch is rated 600VDC 30A, so could be used to test a string of panels.

General-duty switch is not DC rated. It would probably work fine with single panel voltage & current, but I always open circuit with heavy-duty switch.

If I was testing series string, the general duty switch would still be adequate to hold off Voc or carry Isc, but couldn't be expected to interrupt current so heavy duty switch must be used.

A suitable series connection of several heaters could be used as load for this 2000W array, but their resistance would need to be same/similar so no one gets more than 120V applied. Their switches and thermostats are not suitable to interrupt DC, so thermostats are turned all the way up and switches are set without load using ohm meter.

View attachment 63331

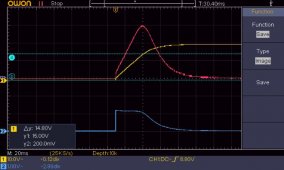

Measuring Voc with heavy duty switch open, Isc with both switches closed, V(load) & I(load) with heavy duty switch closed, general duty switch open

View attachment 63333 View attachment 63334 View attachment 63335