So, I'm trying something a bit different. Instead of putting a BMS on each battery pack, I took a voltage monitor and wired in an active balancer. This monitor is good up to a 24s pack, though I'm just using 13. It shows total voltage, the highest and lowest as well as the difference. The idea is, once a month, I'll go plug in the monitor to each pack, in turn, and if any need balancing, just leave it connected for about an hour, which seems to do the trick, so far. Regular maintenance. So far, this appears to be working just as expected, but the pack has never been significantly out of balance.

I don't trust BMS' and the decent, smart ones are too expensive for my build, at this time. Eventually, I'll probably add a smart BMS to each battery pack, eventually, but I figure this would work well till I could afford the upgrade.

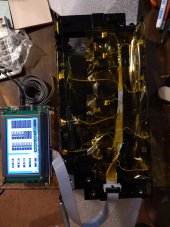

So here's a 13s4p battery pack for my 48 volt power wall. I'm using a ribbon cable for all the cabling. makes wire management so much cleaner. Added the connectors for easy plug and play. These will also sever as the connections for whatever BMS I eventually add, so super convenient and flexible. I'll just have to connect the charge leads.

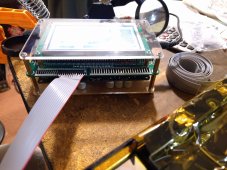

Second pic is the monitor with the active balancer on the bottom. You can make out a series of cans on it...

So, jut looking for a bit of feedback on whether this is a good idea, or what things I need to be weary of, going forward.

Thank you kindly.

I don't trust BMS' and the decent, smart ones are too expensive for my build, at this time. Eventually, I'll probably add a smart BMS to each battery pack, eventually, but I figure this would work well till I could afford the upgrade.

So here's a 13s4p battery pack for my 48 volt power wall. I'm using a ribbon cable for all the cabling. makes wire management so much cleaner. Added the connectors for easy plug and play. These will also sever as the connections for whatever BMS I eventually add, so super convenient and flexible. I'll just have to connect the charge leads.

Second pic is the monitor with the active balancer on the bottom. You can make out a series of cans on it...

So, jut looking for a bit of feedback on whether this is a good idea, or what things I need to be weary of, going forward.

Thank you kindly.