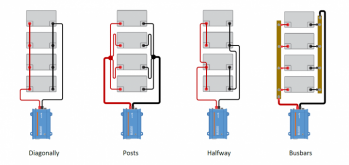

I’m installing 4 12v lithium batteries in parallel. Simple enough to to set them side by side in a row with equal lengths of cable between them. Then attach the main positive cable off one end of the set and the negative off the other end.

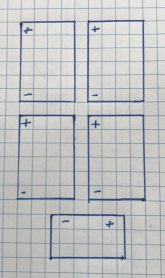

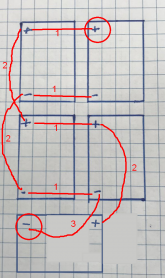

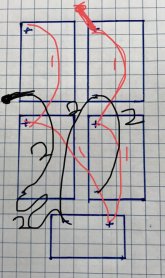

Now, with some rearranging I can add a 5th battery if I need it in the future. With my tray dimensions and the two chassis batteries I would have to place the first four lithiums in side by side pairs and the pairs end on end. Then the fifth one would be placed 90° to the other four and off the end of one pair. Looking at the shortest lengths to the posts gives two 6“, one 10” and one 11 or 12” length for the positive cables and the same for the negative. If I make the cables equal length they will all be 11 or 12” with the ones between the posts on the side by side batteries having a very large curve to them and possible large side force on the terminals.

So, do I need to go with equal lengths cable with a lot of excess of it or size the cable to the distance between corresponding posts making them only as long as necessary for each distance between terminals?

Thanks

Now, with some rearranging I can add a 5th battery if I need it in the future. With my tray dimensions and the two chassis batteries I would have to place the first four lithiums in side by side pairs and the pairs end on end. Then the fifth one would be placed 90° to the other four and off the end of one pair. Looking at the shortest lengths to the posts gives two 6“, one 10” and one 11 or 12” length for the positive cables and the same for the negative. If I make the cables equal length they will all be 11 or 12” with the ones between the posts on the side by side batteries having a very large curve to them and possible large side force on the terminals.

So, do I need to go with equal lengths cable with a lot of excess of it or size the cable to the distance between corresponding posts making them only as long as necessary for each distance between terminals?

Thanks