glowworm238

New Member

- Joined

- Feb 22, 2020

- Messages

- 6

Here are some of the build photo's from my first trailer build. It is a 2020 Runaway 6'X8' Venturist. I bought it last March and due to the current events had plenty of time to build it. Its comes as an empty shell with 1 Shelf and a small window A/C that uses ~ 365W max. I built the interior out of 15 series 80/20 aluminum extrusion and bamboo. I converted the original power system comprising of a 15A shore power plug, a metal wiring box, and 2 power strips to a 24V system that uses 4 UT 1300 batteries, Victron Multiplus Compact 24V/2000/50, SmartSolar MPPT 100/30, 3X HIGHTEC Solar 200W+25% panels wired in series. Its been a fun build and this forum has been a big help in designing my system. It's been fun trying to figure out how to fit everything into such a small area, but everything fit.

Picking up the trailer

Removing front shelf and factory wiring.

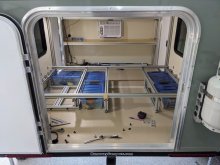

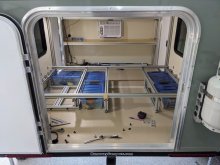

Initial assembly of the interior

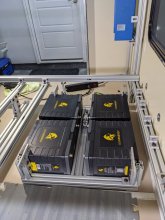

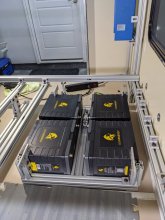

Test fitting battery location. I chose this location due to it being directly over the axle and it would help offset the weight of the propane cylinder and a passenger side awning.

Frame assembled with the T-Fuse and 1/8 rubber for some vibration reduction

Fitting the Smart Shunt and Main battery disconnect. Batteries are wired in a 2S2P configuration with a T-Fuse before the Main battery disconnect.

Initial test fitting of the SCC and Inverter

Rear of the front 120V plug and 3 port 24V power plug

Front 120V plug and 3 port 24V power plug. The factory 15A shore power inlet is run thru the floor under the camper to a 15A circuit breaker in the rear before going to the Inverter. Due to this15A plug, I limited input of the inverter to 14A and turned off the inverters capability to subsidize the shore power.

Picking up the trailer

Removing front shelf and factory wiring.

Initial assembly of the interior

Test fitting battery location. I chose this location due to it being directly over the axle and it would help offset the weight of the propane cylinder and a passenger side awning.

Frame assembled with the T-Fuse and 1/8 rubber for some vibration reduction

Fitting the Smart Shunt and Main battery disconnect. Batteries are wired in a 2S2P configuration with a T-Fuse before the Main battery disconnect.

Initial test fitting of the SCC and Inverter

Rear of the front 120V plug and 3 port 24V power plug

Front 120V plug and 3 port 24V power plug. The factory 15A shore power inlet is run thru the floor under the camper to a 15A circuit breaker in the rear before going to the Inverter. Due to this15A plug, I limited input of the inverter to 14A and turned off the inverters capability to subsidize the shore power.

Last edited: