danielfp248

Battery researcher

- Joined

- Sep 7, 2020

- Messages

- 429

I just got the sample kit of carbon cloth electrodes I will be testing within my cells. It contains the following carbon cloth choices, all from AvCarb (https://www.fuelcellearth.com/fuel-cell-products/carbon-cloth-variety-kit/):

CCP – Carbon Cloth Plain 15 mil thick

CC4P – Carbon Cloth Plain 25 mil thick

CC6P – Carbon Cloth Plain 35 mil thick

HCB-1071 – Carbon Cloth Plain 15 mil thick

Carbon felt they are being compared to (https://www.ceramaterials.com/product/gfe-1-pan-graphite-felt/)

These are all untreated and I will use them as-is.

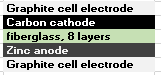

Cell structure will be as follows:

Electrolyte will be 100 uL of ZnBr2 0.5M + TBAB 0.2M, all drawn from the exact same solution.

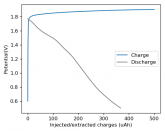

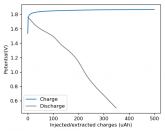

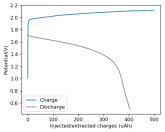

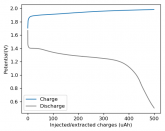

The basic test will be to do 20 cycles at 1mA, charging to 500uAh.

CCP – Carbon Cloth Plain 15 mil thick

CC4P – Carbon Cloth Plain 25 mil thick

CC6P – Carbon Cloth Plain 35 mil thick

HCB-1071 – Carbon Cloth Plain 15 mil thick

Carbon felt they are being compared to (https://www.ceramaterials.com/product/gfe-1-pan-graphite-felt/)

These are all untreated and I will use them as-is.

Cell structure will be as follows:

Electrolyte will be 100 uL of ZnBr2 0.5M + TBAB 0.2M, all drawn from the exact same solution.

The basic test will be to do 20 cycles at 1mA, charging to 500uAh.