I don't think EG inverters support AC coupling.

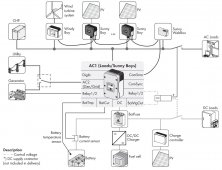

How about using a battery inverter that does (preferably Sunny Island), so it can interact with your GT PV Sunny Boys?

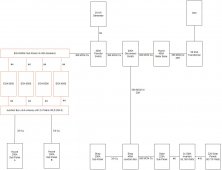

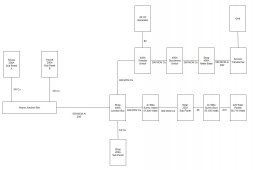

For a split-phase system that backfeeds grid, the max system is 4x SI with 24kW of SB. Once disconnected from grid, more SB could be switched onto it for total of 48kW.

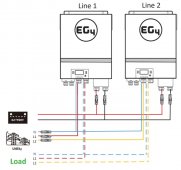

Maybe I'm not interpreting this diagram correctly then:

I would have the grid connected to the Utility input (fed from the transfer switch load side) and my house feeder to the Load output. I know that if I have solar panels connected to the MPPT inputs, those will only charge the battery and NOT feed anything back into the grid. I'm not looking for that since my Sunny Boy inverters are already feeding into the grid and maxing out what the 50 KVA transformer on the street is capable of.

I think what I'm not clear on, is exactly how the EG inverters operate over a typical 24 hour period with utility/grid present on the AC input at all times along with a more or less constant load on the AC output side. Will it just keep the batteries topped off at all times and in the event that I lose grid power, start supplying the load from the batteries? In essence function just like a giant UPS? And if it happens to be daytime, the MPPT inputs will attempt to keep the batteries charged, or at least slow down them being drained.

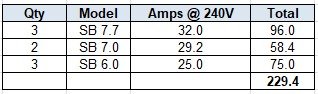

These are the SMA inverters I have:

Discover the Sunny Boy 3.0-US - 7.7-US | SMA America

Discover the Sunny Boy inverter 3.0-US - 7.7-US ► PV performance optimization with SMA ShadeFix ► SMA's SunSpec certified shutdown device

Are you suggesting they can somehow interact with these:

Discover the Sunny Island 4548-US / 6048-US! | SMA America

The efficient island manager Sunny Island 4548-US / 6048-US ► Now with 20 % more power! ► Efficient, simple, flexible and durable! ► Check out now!

Last edited: