I just realized the 56A relay limitation in the SI is @ 120V per your comment above. So that means I would need 8 SIs to be able to backfeed 50kW plus back into the grid. And that's definitely more than I want to spend.

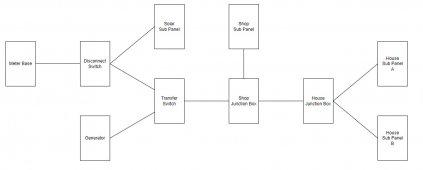

So yeah, let me think about how to redo the diagram to only have some power going through the SIs. Possibly just enough for what 2 SIs can handle, and then have the rest of the SBs direct grid tied.

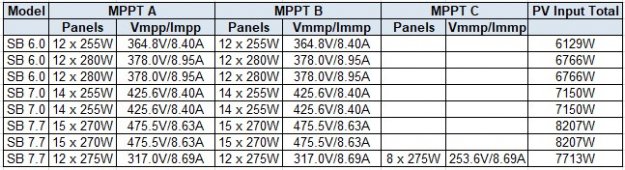

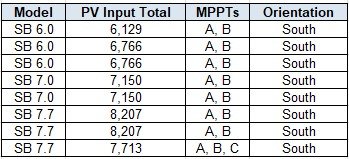

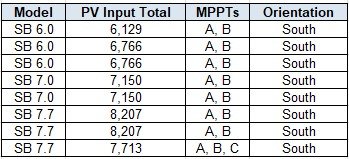

So here are the current PV capacities on my SBs:

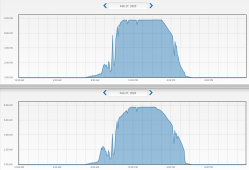

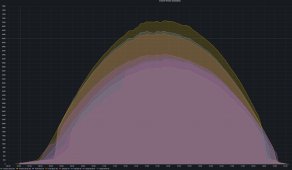

So I think adding a string of East and West facing panels to the 2 SB 7.0s, respectively, which currently have 7,150 watts going to them would be the logical next steep since those are the least over-subscribed. Here's what those 2 were doing on 9/1:

So they definitely have some available overhead.

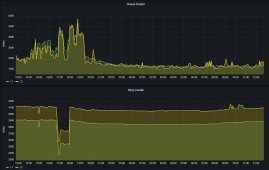

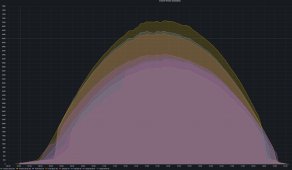

Here are all 8 SBs that day:

So no clipping at all. While there were no clouds in the sky, it was very hot and being 9/1, it was well past the summer solstice.

So yeah, let me think about how to redo the diagram to only have some power going through the SIs. Possibly just enough for what 2 SIs can handle, and then have the rest of the SBs direct grid tied.

So here are the current PV capacities on my SBs:

So I think adding a string of East and West facing panels to the 2 SB 7.0s, respectively, which currently have 7,150 watts going to them would be the logical next steep since those are the least over-subscribed. Here's what those 2 were doing on 9/1:

So they definitely have some available overhead.

Here are all 8 SBs that day:

So no clipping at all. While there were no clouds in the sky, it was very hot and being 9/1, it was well past the summer solstice.

Last edited: