keeeenleee

New Member

- Joined

- Jan 5, 2022

- Messages

- 11

Hi, im a off-grid virgin and after 2weeks of research, I prepared a blueprint. It's 12V camper system with:

Before I make a purchase of all components, I would like to get some feedback if something is wrong or need some optimisation.

Especially I would like some approval about grounding, fuse sizes and corresponding wire sizing.

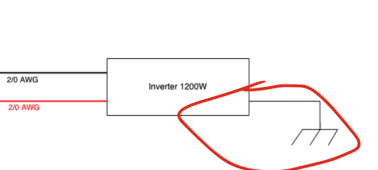

Current situation is that I already have 1200W pure sine inverter and 400W of solar panels, so this are the only two things that I don't want to change, the rest of the diagram is open for discussion.

And at the end, thanks anyone here that help creating such nice community ?

- 200Ah LFP battery

- 400W solar panels

- 1200W inverter

Before I make a purchase of all components, I would like to get some feedback if something is wrong or need some optimisation.

Especially I would like some approval about grounding, fuse sizes and corresponding wire sizing.

Current situation is that I already have 1200W pure sine inverter and 400W of solar panels, so this are the only two things that I don't want to change, the rest of the diagram is open for discussion.

And at the end, thanks anyone here that help creating such nice community ?