TheWanderingJackalopes

New Member

- Joined

- Mar 23, 2022

- Messages

- 27

I have 3 questions...

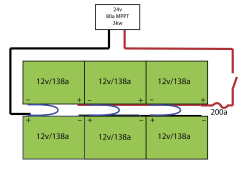

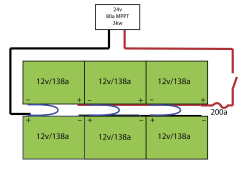

In the process of determining my wire sizes and lengths for wiring my batteries series-parallel, I realized that there are more gaps in my understanding. I have an enclosed space for my LiFePo4 batteries and I want to keep them as close together as possible. They will be laying on their side with the terminals oriented at the top per Valence install specs. As U27 batteries, the cases are 12" on their longest dimension.

I see that it is possible to buy 12" cables, but will they fit given the battery positions I am showing? Or will 12" cables not provide enough "wiggle room"?

I know the wire lengths and sizes need to be identical for all battery to battery connections. Does this rule also apply elsewhere? Can I have heavier gauge wires going from the battery bank to the charge controller?

The wires making my serial connection (+ to -) need to make a 180° turn at the middle. Lighter gauge wire will, of course, bend easier than heavier gauge wire. Given the size of the battery, the configuration, and the MPPT and Inverter, what would be the lightest battery to battery wire I would need and still be safe?

In the process of determining my wire sizes and lengths for wiring my batteries series-parallel, I realized that there are more gaps in my understanding. I have an enclosed space for my LiFePo4 batteries and I want to keep them as close together as possible. They will be laying on their side with the terminals oriented at the top per Valence install specs. As U27 batteries, the cases are 12" on their longest dimension.

I see that it is possible to buy 12" cables, but will they fit given the battery positions I am showing? Or will 12" cables not provide enough "wiggle room"?

I know the wire lengths and sizes need to be identical for all battery to battery connections. Does this rule also apply elsewhere? Can I have heavier gauge wires going from the battery bank to the charge controller?

The wires making my serial connection (+ to -) need to make a 180° turn at the middle. Lighter gauge wire will, of course, bend easier than heavier gauge wire. Given the size of the battery, the configuration, and the MPPT and Inverter, what would be the lightest battery to battery wire I would need and still be safe?