TechnoTime

New Member

- Joined

- May 7, 2021

- Messages

- 38

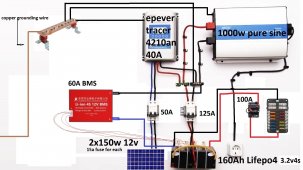

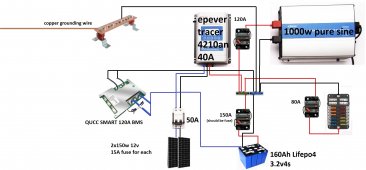

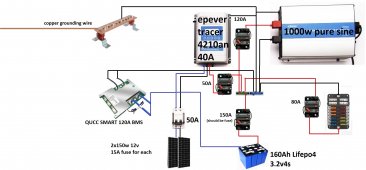

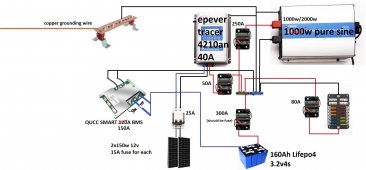

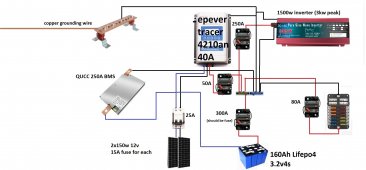

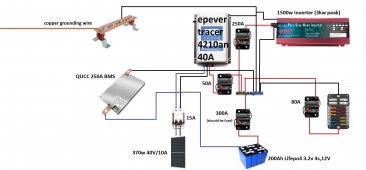

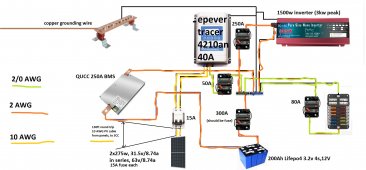

Hello everyone! I'm a total newbie, and this is what I've come up with after a week of research. It's for off grid sauna cabin.

I pretty much only need it for lights, which I plan to run on 12v DC from fuse box (adding some USB outlets for phone / laptop charging). Then I'll have couple of 230v AC sockets as well from my inverter, just in case.

What I'm mostly confused is:

1. Is my BMS big enough and is it OK to connect it the way I did in diagram?

2. Is fuse box connected properly.

3. Are my breakers in proper size?

Batteries gonna be DIY aliexpress cells. All system together is roughly 600 eur (730 usd), so quite cheap. We have proper winter here for a few months, so I'll add DIY automated battery heater, as the electricity box gonna be outside cabin. For those cells, it's written that charging temperature is from -10C, should I trust that or should I never let them charge below 0?

Thanks!

I pretty much only need it for lights, which I plan to run on 12v DC from fuse box (adding some USB outlets for phone / laptop charging). Then I'll have couple of 230v AC sockets as well from my inverter, just in case.

What I'm mostly confused is:

1. Is my BMS big enough and is it OK to connect it the way I did in diagram?

2. Is fuse box connected properly.

3. Are my breakers in proper size?

Batteries gonna be DIY aliexpress cells. All system together is roughly 600 eur (730 usd), so quite cheap. We have proper winter here for a few months, so I'll add DIY automated battery heater, as the electricity box gonna be outside cabin. For those cells, it's written that charging temperature is from -10C, should I trust that or should I never let them charge below 0?

Thanks!

Attachments

Last edited: