Hey, So I got my 8x eve 160ah cells and they are great condition.. I checked all the cells with a multimeter and they all on 3.29v.

But I got some newbie questions..

I got a jbd 250a 4s bms from - https://mullerenergy.com.au/product/12v-250a-jbd-smart-bms-with-bluetooth/

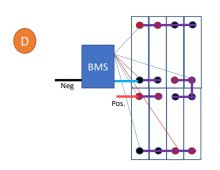

So my main question is about the positive.. When wiring up the cells with the bms wires does the positive that you choose on the cells

have no bus bar - I mean the one that goes direct to the bms.. Also like I see a video setup of that bms and he doesn't put a bus bar which

I'm guessing is correct but does any thicker cable go from the positive on cell to bms or is it just a thicker cable from negative to bms..

Also from the bms where the cable from negative to bms do you add another thick cable ffrom the same negative on the bms to case terminal?

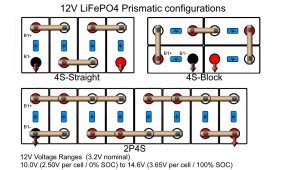

I can show you a picture of the bms and the config I'm looking at doing which is 4s2p..

Also Im going to use my 40ah lithium charger to top balance then use the 5a active balancer the bms has to full top balance it so for

that would it be best to do it in 4 cells at a time or can I do it in the 4s2p?

Any help would be sooo helpful.. also here is the video of the bms -

But I got some newbie questions..

I got a jbd 250a 4s bms from - https://mullerenergy.com.au/product/12v-250a-jbd-smart-bms-with-bluetooth/

So my main question is about the positive.. When wiring up the cells with the bms wires does the positive that you choose on the cells

have no bus bar - I mean the one that goes direct to the bms.. Also like I see a video setup of that bms and he doesn't put a bus bar which

I'm guessing is correct but does any thicker cable go from the positive on cell to bms or is it just a thicker cable from negative to bms..

Also from the bms where the cable from negative to bms do you add another thick cable ffrom the same negative on the bms to case terminal?

I can show you a picture of the bms and the config I'm looking at doing which is 4s2p..

Also Im going to use my 40ah lithium charger to top balance then use the 5a active balancer the bms has to full top balance it so for

that would it be best to do it in 4 cells at a time or can I do it in the 4s2p?

Any help would be sooo helpful.. also here is the video of the bms -