OnTheFlyPDX

New Member

- Joined

- Jun 27, 2021

- Messages

- 18

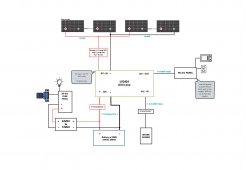

As parts start to arrive, I’m getting pretty close to starting my first solar/lifepo4 build. I’m hoping to get some feedback from you all on my plan and wiring diagram. I have been learning about PV and battery systems on the fly here, so I appreciate any/all feedback. Our travel trailer is a 2010 ORV Creekside 18ck. It’s stock with two lead acid batteries on the tongue and no solar.

Installing MPP LV-2424 hybrid with 24v 200 Ah lifepo4 battery. I’ll use a 24vdc to 12vdc buck converter to tie into the trailer’s DC panel. I will also be removing the trailer’s factory battery charger, as the new lithium batteries will be charged through the LV 2424 with PV or shore power when plugged in.

I’m still shopping for PV, but plan on installing 4x 350-400w used residential panels. There’s quite a bit of variability in voltage and amperage specs on those panels, so I’m still up in the air on whether I’ll run a 2s2p or 4p configuration. The LV 2424 all-in-one I’m using has a PV voltage range of 30-115 VDC (80 A max as well). I have taken into consideration that higher voltage = less voltage drop, but I think I’ll be fine using 8AWG for a 4p setup and it would be more efficient (less affected by shade) than a 2s2p setup. Practically all 350-400w panels have a Vmp over the solar charger’s minimum of 30 V (usually 40-65 Vmp), but is there a reason I should I be aiming to get a higher voltage value out of the PV array with a 2s2p setup?

thanks in advance!!

Installing MPP LV-2424 hybrid with 24v 200 Ah lifepo4 battery. I’ll use a 24vdc to 12vdc buck converter to tie into the trailer’s DC panel. I will also be removing the trailer’s factory battery charger, as the new lithium batteries will be charged through the LV 2424 with PV or shore power when plugged in.

I’m still shopping for PV, but plan on installing 4x 350-400w used residential panels. There’s quite a bit of variability in voltage and amperage specs on those panels, so I’m still up in the air on whether I’ll run a 2s2p or 4p configuration. The LV 2424 all-in-one I’m using has a PV voltage range of 30-115 VDC (80 A max as well). I have taken into consideration that higher voltage = less voltage drop, but I think I’ll be fine using 8AWG for a 4p setup and it would be more efficient (less affected by shade) than a 2s2p setup. Practically all 350-400w panels have a Vmp over the solar charger’s minimum of 30 V (usually 40-65 Vmp), but is there a reason I should I be aiming to get a higher voltage value out of the PV array with a 2s2p setup?

thanks in advance!!