GridWorks Green Solar

Solar Innovator

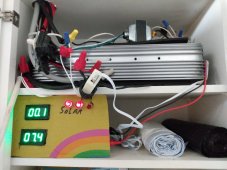

I am surprised someone hasn't asked about the large capacitors in the 2000 watt unit and why that they don't appear on any drawings.

Answer they are dangerous but add considerable kick to motor starting, extra precautions to discharge them before working on the unit is required.

You can talk to me about anything to do with electrical/solar/3D printing and industrial plastic injection molding, made car dash parts for years giant electrical molding machines with robots, production and maintenance.

These no maintenance, fully automatic solar power systems could make a real difference in the upcoming green transition.

Good day ?

Answer they are dangerous but add considerable kick to motor starting, extra precautions to discharge them before working on the unit is required.

You can talk to me about anything to do with electrical/solar/3D printing and industrial plastic injection molding, made car dash parts for years giant electrical molding machines with robots, production and maintenance.

These no maintenance, fully automatic solar power systems could make a real difference in the upcoming green transition.

Good day ?