Both John and DT make good points about expansion. I myself am in the "overboard" category, having repeatedly expanded my systems over the years with bigger batteries, more solar arrays, more electrical demand. The neighbors now joke that I am the local utility, and I should sell power to them.

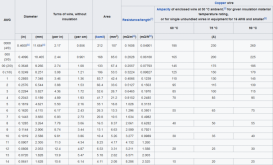

One important point is wiring. Yes copper wire is expensive, and you might be tempted to go with the lightest gauge that will get the job done. I went with overkill, and selected the largest wire (lowest gauge) that would fit in the terminals. As my system has grown over the years, I haven't had to rip out smaller wiring, because I started out large to begin with.

The thing I can tell you is do the wiring once, and be done with it. And, make sure you color code each and every connection so you can see plus vs minus. For me, it was a nightmare helping a neighbor troubleshoot his dead system when it was a mass of mismatched spaghetti of whatever color wire he had at the moment. If you get a good deal on black 4 gauge wire, thats fine. Just wrap some red electrical tape on the termini of that wire so some dumb-ass like me can troubleshoot it. I've even gone to the extent of spray painting my 0/4 wire red so I could connect the positive battery terminal.

What I might do at this point is shift gears and present to you a modest, starter system that could eventually grow by swapping out components. I'll make it 24V, because that's were all the serious electronics start.

4-225Ah 6V golf-cart style batteries 130$ each

1 40Amp Epever MPPT charge controller

4 240W-250W grid-tie Craigslist solar panels 60$ each (wire them in a 2S2P configuration)

24V Samlex sine-wave inverter 520$ (smallest inverter that Samlex makes that can be hard-wired into your main electrical panel) You want a fairly large inverter to start induction loads like your refrigerator.

This comes out to be <1400$. Add a hundred or so for wiring, fuses, breakers, ect and call it 1500$. Add a 500$ HomeDepot generator for 2000$

This should make you 3.0kWh/day of power in December, assuming you have clear weather. As your needs grow, replace with larger batteries, a second or larger charge controller, more panels, a nicer 120/240V split-phase sine-wave inverter.

BTW, I built a single-pole array frame that holds 1000W of panels. I can rotate this left and right to track the daily sun, so in February, I measured 6.1kWh of production. A rotating frame might help you eke out a bit more production with a smaller array.