Regarding some suggestions:

Soldering won't work with aluminum. (brazing would, but it would also require a ton of heat over the entire area)

Welding with a TIG machine in very short bursts with a wet rag between should be fine.

Please don't use an adhesive/epoxy/etc even if it's conductive. Not only is the resistance poor, but almost every conductive compound is very brittle, and placed between those two pieces of aluminum you'd eventually crack and detach.

Laser welding would require a good deal of setup, and you might not get any better penetration than the original supplier got. If you had them re-do the entire bank, maybe it would make sense, but having them do one terminal will probably cost more than simply buying a new battery.

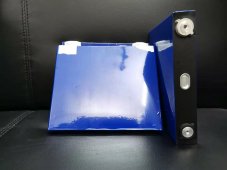

If you cannot get a mechanical drawing of the terminals to determine how much drilling they can accept, I suggest drilling four smaller holes - maybe M4 or M3 - to a depth of 6mm and bottom tap them to 5mm. Then modify the bus bar to accept the four screws, using screws that will extend into the holes the full 5mm. That'll handle all the current that you'd need. Taps and drills are cheap, compared to all the other solutions.

But the real issue is that the weld quality is very poor(insufficient penetration), and if they other terminals are like that, you may want to speak with the supplier and indicate they did a lousy job. Send the same pics, and show that the remaining weld marks on the battery clearly show the weld didn't go deep enough. Ask them to pay for a local place to rework them - all of them. This won't be the only cell that this happens to while you're working with them, I bet.