Bob B

Emperor Of Solar

- Joined

- Sep 21, 2019

- Messages

- 8,606

I am opening this thread to split it off from the general cell compression thread. That way those looking for info don't have to sort thru a thread that has many paths for pack compression.

If you are new to this idea, it stemmed from an EVE cell specification that indicated a significant increase in cell cycle life could be gained by keeping the cells under pressure.

Through the course of the discussion, it has been determined that the optimal pressure would be 12 PSI .... and any pressure above 17 psi would be counter productive.

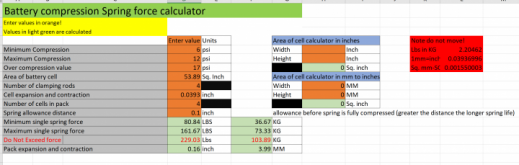

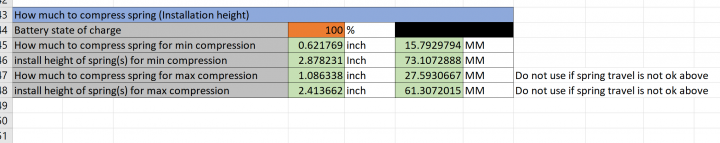

@vtx1029 has gone to the trouble of putting together a spreadsheet to calculate variables depending on springs used and pack sidewall area. He will send it to you if you message him.

If you haven't seen the other thread, it can be found here. https://diysolarforum.com/threads/e...ed-tight-or-spaced-for-expansion.7892/page-23

If you are new to this idea, it stemmed from an EVE cell specification that indicated a significant increase in cell cycle life could be gained by keeping the cells under pressure.

Through the course of the discussion, it has been determined that the optimal pressure would be 12 PSI .... and any pressure above 17 psi would be counter productive.

@vtx1029 has gone to the trouble of putting together a spreadsheet to calculate variables depending on springs used and pack sidewall area. He will send it to you if you message him.

If you haven't seen the other thread, it can be found here. https://diysolarforum.com/threads/e...ed-tight-or-spaced-for-expansion.7892/page-23

Last edited: