jasonhc73

Cat herder, and dog toy tosser.

Does it matter which four points I use to mount my panels to the crossbars?

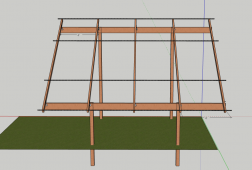

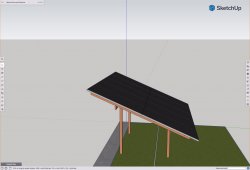

I took out my cad program and setup these models...

My roof is less than 5° tilt, so basically flat.

(I bought 12, and did a really dumb thing, I forgot I only have room for 8)

77x39 panels, so these models are close enough to scale.

Horizontal vs Vertical.

double crossbars VS single crossbars

Mid vs edge.

Does it matter?

I took out my cad program and setup these models...

My roof is less than 5° tilt, so basically flat.

(I bought 12, and did a really dumb thing, I forgot I only have room for 8)

77x39 panels, so these models are close enough to scale.

Horizontal vs Vertical.

double crossbars VS single crossbars

Mid vs edge.

Does it matter?