BillCaswell

New Member

- Joined

- Jan 10, 2020

- Messages

- 78

I am still working to make sense about all of this.That is totally incorrect see my explanation above. I have one and so do hundreds of others. No, absolutely no shunt is fused for the loads or rated current flow. The only fused connection for ANY shunt is for the power lead to power the shunt itself.

This is from the Victron website.

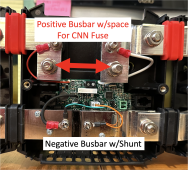

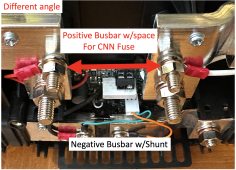

- Lynx Shunt VE.Can - A positive busbar with a space for a main system fuse and a negative busbar with a shunt for battery

monitoring. It has VE.Can communication for monitoring and setup with a GX device.

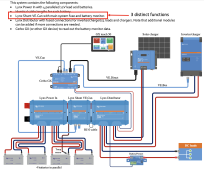

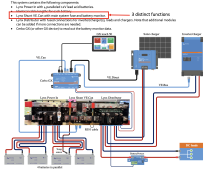

My interpretation is that the lynx shunt product has three functions:

1. Positive busbar (where my questions have been directed)

2. Negative busbar with a shunt for battery

monitoring

3. It has a VE.Can communication for monitoring and setup with a GX device

I've created a bit of a slide set to layout my understanding of how Victron explains their Shunt. From what I can see, it sits in the middle of the lynx distribution system. I am building this for a boat and need to follow the advice of my ABYC certified electronics engineer. He needs to sign off on the design for insurance purposes. For me this NOT about saving a few dollars, but doing it correctly.

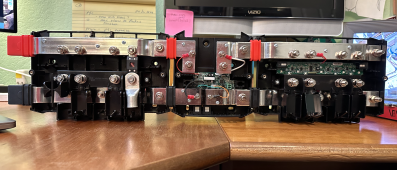

BTW, these are pictures of the hardware siting on my desk.