2manyquestions

New Member

- Joined

- Jul 22, 2021

- Messages

- 26

Hello, everyone.

It appears I am much more of a newb than others here, hence my post in the newcomer section, and my forum handle. On other forums (RC planes, RC cars, and others), I started as a complete newb, some members patiently answered my questions, and I was able to “give back” to other newbs after I gained some experience. I hope to do the same here.

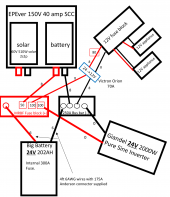

I have attached a mockup of the component wiring diagram I envision, based on my beginner brain. Numbers represent wire gauges, and the one number in a square block is a fuse to the SCC. If I am wrong with how I intend to wire this up, or you have a cleaner way of doing it, your suggestions would be very much appreciated! Please make sure to DUMB DOWN your suggestions for me.

Thus far, I have read through Will’s book on DIY Mobile Solar Power (1st edition) and watched several of his beginner videos.

So, here are my questions:

Thank you so much!!

It appears I am much more of a newb than others here, hence my post in the newcomer section, and my forum handle. On other forums (RC planes, RC cars, and others), I started as a complete newb, some members patiently answered my questions, and I was able to “give back” to other newbs after I gained some experience. I hope to do the same here.

I have attached a mockup of the component wiring diagram I envision, based on my beginner brain. Numbers represent wire gauges, and the one number in a square block is a fuse to the SCC. If I am wrong with how I intend to wire this up, or you have a cleaner way of doing it, your suggestions would be very much appreciated! Please make sure to DUMB DOWN your suggestions for me.

Thus far, I have read through Will’s book on DIY Mobile Solar Power (1st edition) and watched several of his beginner videos.

So, here are my questions:

- My Big Battery is 24V battery and my solar charge controller and inverter are compatible with this voltage. Is it ok to use a wire gauge chart for a 12V system?

- My battery comes with an integrated 300 amp fuse…is this in place of the bolt on fuse that typically goes on the positive battery terminal?

- My Big Battery 24V 202AH battery came with a 175 amp Anderson connector with 6 AWG 105 degree C wires. I am assuming the ones supplied are ok?

- In some drawings in Will’s book, several (+) or (-) wires “meet together” and continue along one wire, but I don’t exactly know how they are all connected to one. How would that be done for negative wires? And for positive wires (bolt on fuse)? I do not know how to do this.

- Since I don’t know the answer to question 4 above, I thought I could use one main negative bus and one main positive bus to join the different positive and negative wires per my diagram. Is that ok? If I were to use the bus bars per my diagram, and since they would provide up to 166 amps to the inverter (4000W surge), 40 amps to my charge controller, and maybe another 25 amps to the fuse block, would each bus need to be rated at least 250 amps?

- I realize I will need a 24V to 12V step down converter to power my 12V appliances. Anyone want to recommend a good one? Where is the best place to wire that in?

- The Blue Sea Systems fuse block linked from Will’s website (with negative and cover) appears to be able to take the negative lead from the appliances. So, it appears there is no need to connect to a separate negative bus, correct?

Thank you so much!!