chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,184

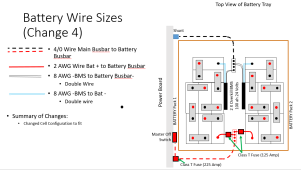

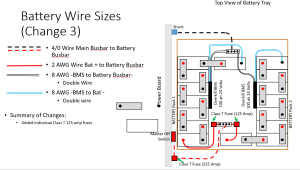

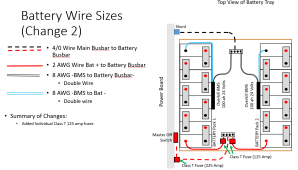

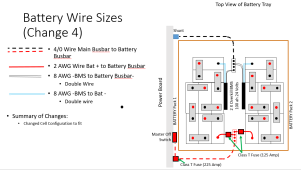

Welcome comments on my diagram prior to assembling these 2 X 8S 214 volt total of 560 ah build for my RV. I am putting these in a slide out battery tray, so this limits how to place the cells. 8S will fit in the 24 1/4" Wide 24" tall picture, but once compression and material between cells is taken into account, the cells don't fit.

-Drawn to scale: the Brown Box is a slideout battery tray; Eve 280 cells are black boxes

-Not drawn to scale are the Class t fuse holders (7" X 2"), busbars (7" X 2" long), and Overkill BMS (Oddly enough, don't see dimensions, but will fit in the space shown).

-Drawn to scale: the Brown Box is a slideout battery tray; Eve 280 cells are black boxes

-Not drawn to scale are the Class t fuse holders (7" X 2"), busbars (7" X 2" long), and Overkill BMS (Oddly enough, don't see dimensions, but will fit in the space shown).