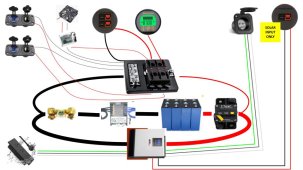

Whipped up the diagram in Google Sheets. I'm just looking for any critiques or callouts in my modest 12V build. I built Will's milk crate build previously and wanted to make something a bit 'nicer'. I'm eager to read any feedback.

Highlights are:

One thing I think I might be missing is an inline fuse on the solar input going into the inverter.

Other than that, I'm feeling pretty confident about this build!

Highlights are:

- 280Ah cells

- Overkill 120A BMS

- MPP Solar 1012LV-MS inverter (1000W)

- 4 AWG wire between the battery-BMS-shunt/breaker and the inverter

- I used 2 AWG in a previous build with the same MPP inverter but 4 is supposed to be good to 100A, I believe? Please correct me if I'm wrong

- 30A Powerpoles (12 AWG)

One thing I think I might be missing is an inline fuse on the solar input going into the inverter.

Other than that, I'm feeling pretty confident about this build!

Attachments

Last edited: