Hi folks long time lurker first time poster. Hopefully you can help me avoid building a fire hazard here.

I am building a 12 volt electrical bank to support a high current draw 100-250A continuous with 300A spikes. Hopefully you can help me clarify the best wiring configuration to make this work together safely or let me know if I need additional components. I am concerned about the BMS inside the Chins LifepO4 Bank. The specs give a max charge of 50A and max discharge of 100A. That is far below the 300A spikes it could see. After watching Will's video it looks like I can open the battery and upgrade all of the contacts, busbars and wires to thicker larger gauge but I am not sure if the components on the BMS are the actual bottleneck. If the BMS is the bottleneck can I add another BMS in Parallel to increase capacity? What BMS would you recommend?

Any input would be appreciated. I really want to get this right the first time and avoid frying equipment.

Components I have so far

1)The Chins LifepO4 he recommended here

2)Victron Energy 500A Smart Shunt

3)Maxwell Durablue 16V 500Farad Super Capacitor https://maxwell.com/products/ultracapacitors/modules/

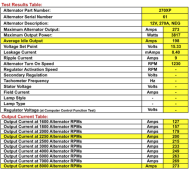

4)DC Power High 270A High Output alternator https://cdn.shopify.com/s/files/1/0...-40fb-b418-46a4f9816d3f_900x.png?v=1549863543

5)12v XS Power AGM Battery

The BMS Specs are

Rated Capacity (0.2C): 100Ah / 1280Wh

Cycle life: 2000+ cycles at 80% discharge depth

Rated voltage: 12.8V

Charge voltage: 14.2 - 14.6V

Depth of Discharge (DoD): 100%

Standard charge current: 20A

Charging time: Approximately 6 hours

Max continuous charge current: 50A

Max continuous discharge current: 100A

Peak discharge current: 300A (Duration: less than 5 seconds)

Operating temperatures: Charge 0°C~50°C(32°F~122°F),

Discharge -20°C~60°C(-4°F~140°F), Storage -20°C~50°C(-4°F~122°F)

Impedance: ≤ 10mΩ

Thank you!

I am building a 12 volt electrical bank to support a high current draw 100-250A continuous with 300A spikes. Hopefully you can help me clarify the best wiring configuration to make this work together safely or let me know if I need additional components. I am concerned about the BMS inside the Chins LifepO4 Bank. The specs give a max charge of 50A and max discharge of 100A. That is far below the 300A spikes it could see. After watching Will's video it looks like I can open the battery and upgrade all of the contacts, busbars and wires to thicker larger gauge but I am not sure if the components on the BMS are the actual bottleneck. If the BMS is the bottleneck can I add another BMS in Parallel to increase capacity? What BMS would you recommend?

Any input would be appreciated. I really want to get this right the first time and avoid frying equipment.

Components I have so far

1)The Chins LifepO4 he recommended here

4)DC Power High 270A High Output alternator https://cdn.shopify.com/s/files/1/0...-40fb-b418-46a4f9816d3f_900x.png?v=1549863543

5)12v XS Power AGM Battery

The BMS Specs are

Rated Capacity (0.2C): 100Ah / 1280Wh

Cycle life: 2000+ cycles at 80% discharge depth

Rated voltage: 12.8V

Charge voltage: 14.2 - 14.6V

Depth of Discharge (DoD): 100%

Standard charge current: 20A

Charging time: Approximately 6 hours

Max continuous charge current: 50A

Max continuous discharge current: 100A

Peak discharge current: 300A (Duration: less than 5 seconds)

Operating temperatures: Charge 0°C~50°C(32°F~122°F),

Discharge -20°C~60°C(-4°F~140°F), Storage -20°C~50°C(-4°F~122°F)

Impedance: ≤ 10mΩ

Thank you!

Last edited: