Hi! I need yall's help again.... So. . . .

I bought solar panels. Six 440 Watt panels

I bought the AC-300 solar generator w 4 batteries

I bought to help with the solar charging: PV Voltage Step Down Module (D300S)

Last step, I need to buy cables.

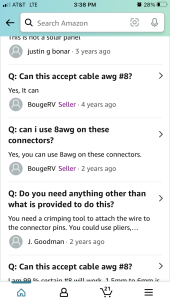

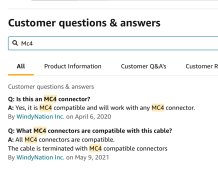

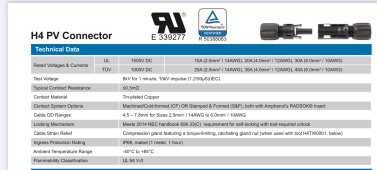

I figure my solar panels will be about 100-125 feet from my AC-300. I would like to buy the cables that already have the MC4 connections attached.

Would 10 AWG be okay? Also, what configuration would be best to set this up? (3 series, 2 parallel? Or 2 series, 3 parallel? Or just 6 straight into the AC-300???)

SPECS

Solar panels:

440 watt each (Bought six of them for a total of 2,640 watts)

VOC = 49.62

VMP = 40.99

IMP = 10.74

AC-300

Solar Input: 2400 watts, (12-150V), 2x12A

PV Voltage Step Down Module (D300S)

Accept 3000W Max Input Power

Step down the voltage of rigid panels to 120V from 550V

Starting voltage = 120V

Max DC input current = 15A

THANK YOU!!!!!!!!!

I bought solar panels. Six 440 Watt panels

I bought the AC-300 solar generator w 4 batteries

I bought to help with the solar charging: PV Voltage Step Down Module (D300S)

Last step, I need to buy cables.

I figure my solar panels will be about 100-125 feet from my AC-300. I would like to buy the cables that already have the MC4 connections attached.

Would 10 AWG be okay? Also, what configuration would be best to set this up? (3 series, 2 parallel? Or 2 series, 3 parallel? Or just 6 straight into the AC-300???)

SPECS

Solar panels:

440 watt each (Bought six of them for a total of 2,640 watts)

VOC = 49.62

VMP = 40.99

IMP = 10.74

AC-300

Solar Input: 2400 watts, (12-150V), 2x12A

PV Voltage Step Down Module (D300S)

Accept 3000W Max Input Power

Step down the voltage of rigid panels to 120V from 550V

Starting voltage = 120V

Max DC input current = 15A

THANK YOU!!!!!!!!!