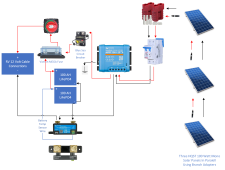

Thanks to all I have learned here and from reviewing various videos and online forums and Victron videos and manuals, I have drawn up a diagram for a simple 300 watt portable solar system I am planning as part of a change of our trailer's lead acid batteries to lithium and adding a portable solar panel set I built from HQST 100 watt panels. We will hopefully upgrade to a big inverter/charger later, after we can afford an inverter and more batteries and panels.

For now, we just want to help keep the lithium batteries charged enough to run the 12 volt only refrigerator and some lighting. We have a pair of Hondas if we really need to run the AC, or to top off the batteries while boondocking on cloudy days and the solar doesn't keep up.

The trailer's converter is a WFCO Auto-Detect that has the correct charge profile for lithium batteries.

I'd appreciate everyone's input on how I could improve the setup, or if I have anything missing or in the wrong place.

Also, I have a question I haven't seen answered. The Victron solar charge controller has a ground screw on the side that I am not sure exactly where it should be wired to, or how big the wire should be. Do I run it to the travel trailer's frame?

"Chassis grounding

A separate ground path for the chassis ground is permitted because the chassis is isolated from the positive and the negative terminals."

Thanks for all the great advice and knowledge shared here!

(Edited to update drawing...)

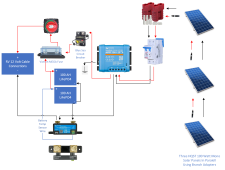

For now, we just want to help keep the lithium batteries charged enough to run the 12 volt only refrigerator and some lighting. We have a pair of Hondas if we really need to run the AC, or to top off the batteries while boondocking on cloudy days and the solar doesn't keep up.

The trailer's converter is a WFCO Auto-Detect that has the correct charge profile for lithium batteries.

I'd appreciate everyone's input on how I could improve the setup, or if I have anything missing or in the wrong place.

Also, I have a question I haven't seen answered. The Victron solar charge controller has a ground screw on the side that I am not sure exactly where it should be wired to, or how big the wire should be. Do I run it to the travel trailer's frame?

"Chassis grounding

A separate ground path for the chassis ground is permitted because the chassis is isolated from the positive and the negative terminals."

Thanks for all the great advice and knowledge shared here!

(Edited to update drawing...)

Last edited: