After patiently waiting for my cells to cross the ocean and arrive at my door, upon unboxing them, I was less than thrilled to discover that my terminals have been tapped quite crooked.

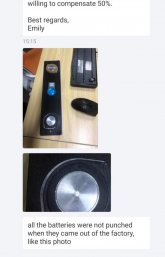

Is this typical? I can't believe that I'm the only person who has received cells with such poorly tapped terminals, but I couldn't find any mention of this happening to anyone else on the forum. These pictures show a couple of the worst examples, but they are all clearly tapped by hand with varying degrees of misalignment. For clarity, I've run 20mm M6 grub screws down the to bottom of the hole for the pictures.

Can I use these batteries as-is? I brought this to the attention of the reseller on Alibaba and was told that their "engineer" said it would be fine. Well, I'm an engineer, and I don't think these will be fine - when clamped, the load on the terminals will introduce significant stress due to the unequal loading from the single point of contact under the fastener head.

I'd appreciate any thoughts on how to proceed. Clamp them up and hope for the best? Demand a refund? Drill and tap with M8? Drill and helicoil to M6 or 1/4-20? I really don't want to spend a weekend trying to save these cells and risk the potential of damaging them. I have a small drill press but do not have access to a proper machine shop.

- uberpixel

Is this typical? I can't believe that I'm the only person who has received cells with such poorly tapped terminals, but I couldn't find any mention of this happening to anyone else on the forum. These pictures show a couple of the worst examples, but they are all clearly tapped by hand with varying degrees of misalignment. For clarity, I've run 20mm M6 grub screws down the to bottom of the hole for the pictures.

Can I use these batteries as-is? I brought this to the attention of the reseller on Alibaba and was told that their "engineer" said it would be fine. Well, I'm an engineer, and I don't think these will be fine - when clamped, the load on the terminals will introduce significant stress due to the unequal loading from the single point of contact under the fastener head.

I'd appreciate any thoughts on how to proceed. Clamp them up and hope for the best? Demand a refund? Drill and tap with M8? Drill and helicoil to M6 or 1/4-20? I really don't want to spend a weekend trying to save these cells and risk the potential of damaging them. I have a small drill press but do not have access to a proper machine shop.

- uberpixel