Ok so I have done a ton of research and browsing of various threads on this forum, probably for a good two weeks now. I am in the process of installing a 36 panel bifacial array that will be ground mounted in the pasture next to my house near my utility pole, which is where my equipment shed will be.

My thoughts leading up to this design, based on all the research are basically:

- all metal designs/kits are way too expensive for me (says the guy who bought 18kW of panels...)

- mounting panels directly to wood is probably not a good idea even though you can get it to work

- unistrut is expensive

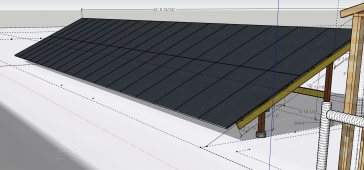

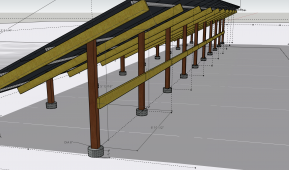

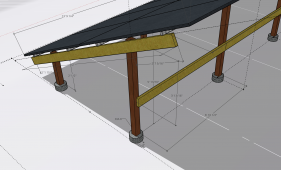

So I've decided to mash together everything I've seen others doing in this same situation and came up with the following, which I think is pretty simple:

- build the frame out of 4x4 (vertical supports) and 2x6 (panel supports/cross members)

- anchor 4x4 vertical supports to concrete piers, with one north and one south support every 2 panels

- use iron ridge horizontal rails to mount the panels, in two rows of 18

No I did not hire an engineer to vet this design. I did some back of the napkin math for static load along with expected wind force and snow load (both pretty light in my area) and went above and beyond that (as far as I can tell anyway). I will be treating the heck out of the wood and reapplying every couple years to make sure it lasts as long as possible.

Anyone see any glaring issues with this? here are some pictures from sketchup with dimensions shown.

My thoughts leading up to this design, based on all the research are basically:

- all metal designs/kits are way too expensive for me (says the guy who bought 18kW of panels...)

- mounting panels directly to wood is probably not a good idea even though you can get it to work

- unistrut is expensive

So I've decided to mash together everything I've seen others doing in this same situation and came up with the following, which I think is pretty simple:

- build the frame out of 4x4 (vertical supports) and 2x6 (panel supports/cross members)

- anchor 4x4 vertical supports to concrete piers, with one north and one south support every 2 panels

- use iron ridge horizontal rails to mount the panels, in two rows of 18

No I did not hire an engineer to vet this design. I did some back of the napkin math for static load along with expected wind force and snow load (both pretty light in my area) and went above and beyond that (as far as I can tell anyway). I will be treating the heck out of the wood and reapplying every couple years to make sure it lasts as long as possible.

Anyone see any glaring issues with this? here are some pictures from sketchup with dimensions shown.