OffGridInTheCity

Solar Wizard

One advantage of mounting the panel at an angle is the rain will clean them. Mine are FLAT and the rain can't run off 100% because of the lip on the panel frame - so water pools / evaporates and dirt residue is left.aren't you cutting a hole for the A/C Unit? Is the location fixed?

Here my take on aerodynamics the solar hump:

Solar "Hump" for aerodynamics for Class A RV

I'm currently fitting large 435W on my RV. (82x 40 inches) My idea is to fit the long edge (82 inches) across the roof and create a kind of spoiler hump in the front of the RV. (Primary use - is to clear above the vent) This is recently done in Bus design and I saw it on some newer Class C...diysolarforum.com

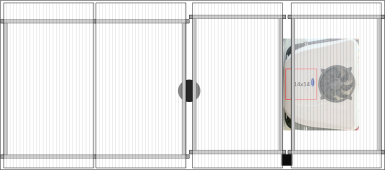

assuming that the right side of the picture is forward of your camper. You could angle the first panel to protect the following panels and the remaining panels are flat on the roof. So basically - the first panel is a spoiler while driving down the road and directing the wind up.

Move the A/C unit further forward - so that is only underneath one panel - the first one.

View attachment 78325

Maybe tip Panels 2-4 up a bit as well and make sure Panel 1 and AC don't shadow Panels 2-4 as any shadow, even a few square inches will cut power to nothing. And as a bonus you might get just a bit more power if you park facing the sun