coreyzev

New Member

- Joined

- Sep 18, 2021

- Messages

- 41

Pre-posting edit note: Hindsight I figured out while posting this, I had not matched the units' magnitude while comparing resistances, and they're much closer than I thought, by about 10^2. I am now fixating MUCH less, but still curious what people think of the differences between the two, so the post will continue as follows.

------

TLDR: I dont wanna undersize my sub-par grade 6303 aluminum busbars.

---

Hi all, due to availability and cost I bought 32ft (9.7m) of aluminum flat bar stock from the big box hardware store. It's 3/4" wide by 1/8" thick, and I was gonna double it up to be 1/4" thick. (19mm w x 3.175mm th). I could return it, but I would like to use what I have in front of me, closest big store is an hour away, and idk if there's anywhere near me to get copper. These were also 1/4 the price of copper or 6101 aluminum, which has led to the following concerns.

I've found myself hyper-fixating on figuring out the actual conductive properties of this 6063-T5 grade aluminum, specs suggest it's got a 55% IACS conductivity rating.But they also say it's got a much higher resistance than pure copper or aluminum (*note above*). It's still more resistive than pure alu, but not as much as i thought. (not sure how that stuff works). Pure aluminum by IACS standards is about 61%. And I assume this is how most calculations for aluminum stock ampacity are done. 6061 alu is 59% IACS. Copper is 100% IACS. I tried measuring its conductivity w/ my DMM but it was not good enough.

Does that 4% IACS by volume make that big of a difference to be worth 4x as much?

For significantly more context and data, click here:

All that data and I still don't know exactly how big I need my 6063 Busbars to be. And the higher resistivity still concerns me for heat.

------

TLDR: I dont wanna undersize my sub-par grade 6303 aluminum busbars.

---

Hi all, due to availability and cost I bought 32ft (9.7m) of aluminum flat bar stock from the big box hardware store. It's 3/4" wide by 1/8" thick, and I was gonna double it up to be 1/4" thick. (19mm w x 3.175mm th). I could return it, but I would like to use what I have in front of me, closest big store is an hour away, and idk if there's anywhere near me to get copper. These were also 1/4 the price of copper or 6101 aluminum, which has led to the following concerns.

I've found myself hyper-fixating on figuring out the actual conductive properties of this 6063-T5 grade aluminum, specs suggest it's got a 55% IACS conductivity rating.

Does that 4% IACS by volume make that big of a difference to be worth 4x as much?

For significantly more context and data, click here:

Specs of 6063-T5 found here: http://www.matweb.com/search/DataSheet.aspx?MatGUID=79875d1b30c94af39029470988004fb6

It seems like most providers of aluminum busbars use 6101 aluminum. McMaster-Carr sells 6101-T61 for their conductive aluminum. But it's $60/6ft vs $15/6ft for 6063.

So I've been looking at the numbers comparing the two trying to figure out exactly how thick I need to make these or if I just need to use something else (before I cut into them). They're going to be hidden away and very snug, so if they get too hot I likely wont be able to get to them in time to save from disaster.

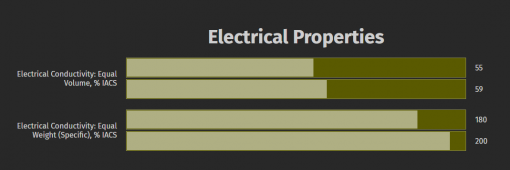

I found this site, makeitfrom.com which compares the 2 grades of aluminum for me, this is their section on electrical but it doesn't mean much to me aside from one number is bigger than another. And they've got nearly identical thermal conductivity, 210 vs 220 W/m-K

www.makeitfrom.com

www.makeitfrom.com

FilterGuy made this diagram of my battery setup. It'll be a 48v 300ah 16s3p LiFePo4 pack.

So each set of 3P will be directly connected in series to the next pack of 3P via a single busbar, 3 bolts, 1 thru each set of red & black.

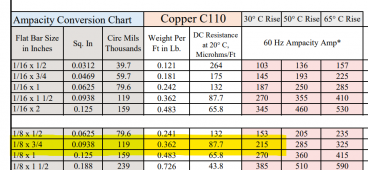

And for one last bit of overkill:

It seems like most providers of aluminum busbars use 6101 aluminum. McMaster-Carr sells 6101-T61 for their conductive aluminum. But it's $60/6ft vs $15/6ft for 6063.

So I've been looking at the numbers comparing the two trying to figure out exactly how thick I need to make these or if I just need to use something else (before I cut into them). They're going to be hidden away and very snug, so if they get too hot I likely wont be able to get to them in time to save from disaster.

I found this site, makeitfrom.com which compares the 2 grades of aluminum for me, this is their section on electrical but it doesn't mean much to me aside from one number is bigger than another. And they've got nearly identical thermal conductivity, 210 vs 220 W/m-K

6063-T5 Aluminum vs. 6101-T61 Aluminum :: MakeItFrom.com

FilterGuy made this diagram of my battery setup. It'll be a 48v 300ah 16s3p LiFePo4 pack.

So each set of 3P will be directly connected in series to the next pack of 3P via a single busbar, 3 bolts, 1 thru each set of red & black.

And for one last bit of overkill:

| Material | Resistivity | Conductivity | Price Per 6ft (1/4" x 3/4") |

| Pure Aluminum | 2.65e−8 ohm-m | 61% IACS | N/A |

| 6063-T5 Alu | 3.16e-8 ohm-m | 55% IACS | $15.32 |

| 6101-T61 Alu | 2.99e-8 ohm-m | 59% IACS | $58.39 |

| Pure Copper | 1.68e−8 ohm-m | 100% IACS | N/A |

| 110 Copper | 1.71e-8 ohm-m | 101% IACS | $71.55 |

All that data and I still don't know exactly how big I need my 6063 Busbars to be. And the higher resistivity still concerns me for heat.