shortyjacobs

New Member

- Joined

- Mar 8, 2021

- Messages

- 21

I'm brand new to this and learning as I go. Got in 4x 202AH cells from BLMPOW on aliexpress, working on charging them up. Cells, by the way, look great, come with m6 posts that look welded on. Was top balancing from scratch, thinking "5 amp rate, 202 ah, max time will be 20 hrs....", while forgetting that I had them in parallel. Duh.

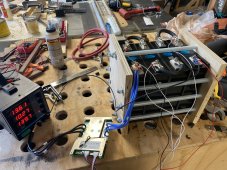

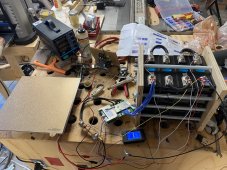

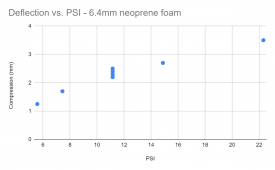

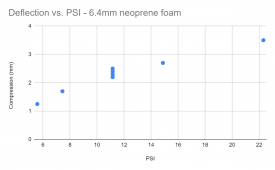

Decided I wanted a compression frame, hook up the overkill BMS, and series charge them up to HVD on a cell before doing the top balancing. Figured foam was a good option - saw the thread on foam compression frames, but didn't want to pay for the expensive Granger foam, (or wait for it). Got quarter inch neoprene from Amazon, prime, and did a quick pressure/compression calibration:

Decided I want around 2.4mm per layer of foam compression to get 12 PSI, with a max of 2.8mm and min of 2.0mm. Added up the battery thickness, foam thickness, and subtracted 2.4mm x 5 layers of foam to get a final pack width. I used 3/8" allthread with 1/2" OD polyethylene tubing over it for the compression, and cut the tubing to the exact size I want the pack to be after compression. What do you think? Have I missed something here? Does this look safe/OK?

Decided I wanted a compression frame, hook up the overkill BMS, and series charge them up to HVD on a cell before doing the top balancing. Figured foam was a good option - saw the thread on foam compression frames, but didn't want to pay for the expensive Granger foam, (or wait for it). Got quarter inch neoprene from Amazon, prime, and did a quick pressure/compression calibration:

Decided I want around 2.4mm per layer of foam compression to get 12 PSI, with a max of 2.8mm and min of 2.0mm. Added up the battery thickness, foam thickness, and subtracted 2.4mm x 5 layers of foam to get a final pack width. I used 3/8" allthread with 1/2" OD polyethylene tubing over it for the compression, and cut the tubing to the exact size I want the pack to be after compression. What do you think? Have I missed something here? Does this look safe/OK?