Frank in Thailand

making mistakes so you don't have to...

I know this is not the correct forum part to ask this.

The usage is.

LOCTITE-28654-Form-A-Thread-NEW-Henkel-Loctite-236382 !!

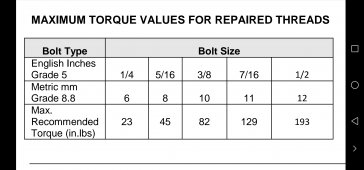

Apparently able to withstand 170lbs torque. (Not sure what size bolt)

The (possible) best solution to fix the ripped out threads without any additional tools needed!!!

I really like to try and inform you guys of the usability.

Available on:

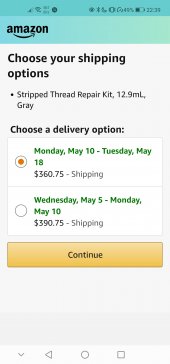

For me (Thailand) that's +/-$20 for the product, + $30 for transport + $28 for pre-paid tax...

Or buy local webshop for +/- 6000 THB ($192,-) (still shipped from USA)

As you can understand, absurd for a product for $10-25 (I can find different suppliers online with different price range)

I paid one time $30 extra to get ox-gard, still absurd on $15 product price, but atleast it's a big tube.

Who can help me purchase and sent per express normal post to Thailand??

It's small and light, should fit in a normal envelope.

(Best via PM)

Naturally I can pay for the product and shipment via PayPal or so.

The usage is.

LOCTITE-28654-Form-A-Thread-NEW-Henkel-Loctite-236382 !!

Apparently able to withstand 170lbs torque. (Not sure what size bolt)

The (possible) best solution to fix the ripped out threads without any additional tools needed!!!

I really like to try and inform you guys of the usability.

Available on:

LOCTITE - 28654 Form-A-Thread - NEW Henkel Loctite 236382, PC 3967 79340286542 | eBay

Find many great new & used options and get the best deals for LOCTITE - 28654 Form-A-Thread - NEW Henkel Loctite 236382, PC 3967 at the best online prices at eBay! Free shipping for many products!

www.ebay.com

For me (Thailand) that's +/-$20 for the product, + $30 for transport + $28 for pre-paid tax...

Or buy local webshop for +/- 6000 THB ($192,-) (still shipped from USA)

As you can understand, absurd for a product for $10-25 (I can find different suppliers online with different price range)

I paid one time $30 extra to get ox-gard, still absurd on $15 product price, but atleast it's a big tube.

Who can help me purchase and sent per express normal post to Thailand??

It's small and light, should fit in a normal envelope.

(Best via PM)

Naturally I can pay for the product and shipment via PayPal or so.