You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

resisters as the heater

- Thread starter Mojobus

- Start date

ericfx1984

Solar Enthusiast

- Joined

- Oct 10, 2021

- Messages

- 740

Well sure, technically a heating element is just that, a resistor...

ericfx1984

Solar Enthusiast

- Joined

- Oct 10, 2021

- Messages

- 740

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,843

How did you come up with that calculation?But that would mean 6 x 25w =150W heating power, which is too high. Probably the load resistors would not withstand this in continuous operation. How can I simply limit the current?

I need maybe 20-30Watt heating power

What is the resistance of those resistors? If you want to dissipate 30W of power @12V then the load resistance will be 4.8 Ohms.

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,843

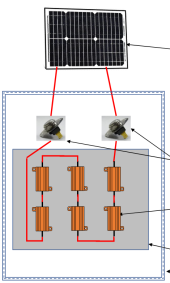

Six 10 Ohms resistors in series = 10 Ohms * 6 = 60 Ohms.resistors 10 Ohm

Using Ohms law: E = I *R

Current (I) through the 60 Ohms of resistance (R) = E/ R = 12V/60 Ohms = 0.20A

Power dissipation = I * E = 0.20A * 12V = 2.40W

You can connect just three 10 Ohms resistors in parallel, the total resistance will be 3.33 Ohms.

So the power dissipation will be about 43W.

Series, parallel resistor calculator:

Conversion Calculator Parallel and Series Resistor | DigiKey

Calculate the total series and parallel resistance of a circuit using DigiKey's Parallel and Series Resistor calculator.

www.digikey.com

Last edited:

Horsefly

Solar Wizard

You can buy nichrome, stainless, and kanthal resistance wire for substantially less than the resistors. Just wind it up in a coil, and test the resistance with a multimeter.

Nichrome 80-50' - 20 Gauge Resistance Wire https://www.amazon.com/dp/B07CHTY1VV/ref=cm_sw_r_apan_glt_fabc_GYD400S6BR59BMPXR458

Nichrome 80-50' - 20 Gauge Resistance Wire https://www.amazon.com/dp/B07CHTY1VV/ref=cm_sw_r_apan_glt_fabc_GYD400S6BR59BMPXR458

S Davis

Solar Enthusiast

- Joined

- Sep 25, 2021

- Messages

- 584

Attachments

100 Proof

"Please Lord, don't let me do something stupid."

- Joined

- Feb 14, 2021

- Messages

- 206

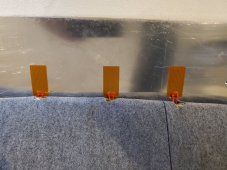

I used 4 of these 7W polyimide heaters. https://www.amazon.com/gp/product/B07P2RJDPL. I attached them to a .060” aluminum plate I had and covered them with felt and Kapton tape. I covered the other side of the plate with phenolic tape to give the cells something to slide on as they expand and contract in my compression fixture. At only 28 Watts, they heat my cells gently and evenly. Of course, the whole thing is in an insulated box.

Attachments

Horsefly

Solar Wizard

I did some testing with those same heating pads. They were actually the first ones I tried. In my tests, they got way too hot way too fast. Although they are only 7W, the max temperature they are spec'd at is 100°C, which is 212°F. That is really hot. I think the silicone heating pads (larger area, and usually limited to 60°C) are better for this application.I used 4 of these 7W polyimide heaters. https://www.amazon.com/gp/product/B07P2RJDPL. I attached them to a .060” aluminum plate I had and covered them with felt and Kapton tape. I covered the other side of the plate with phenolic tape to give the cells something to slide on as they expand and contract in my compression fixture. At only 28 Watts, they heat my cells gently and evenly. Of course, the whole thing is in an insulated box.

100 Proof

"Please Lord, don't let me do something stupid."

- Joined

- Feb 14, 2021

- Messages

- 206

The heaters themselves might very well get that hot if not attached to anything as they have almost no thermal mass and little surface area to dissipate heat. After I attached them to the aluminum plate, I could not get the PLATE hotter than 110 degrees. That was in air with no mass attached. Sitting under the battery transfering heat to the cells, the plate never gets anywhere near that hot.

Horsefly

Solar Wizard

Ok, to each his own. My testing was not in air. The heaters were Kapton taped to an aluminum plate with jars on water on top. Still got too hot too fast for my taste. In my opinion (only an opinion) setting your pain threshold at 110°F is too high. I don't think the plate should get above 85°F.The heaters themselves might very well get that hot if not attached to anything as they have almost no thermal mass and little surface area to dissipate heat. After I attached them to the aluminum plate, I could not get the PLATE hotter than 110 degrees. That was in air with no mass attached. Sitting under the battery, the plate never gets anywhere near that hot.

See my other posts graphing the heating of my 8S 230Ah battery. I used two 12V 12W silicone heating pads, roughly 100mm x 120mm. I've found that to move my cells from 50°F to 60°F in my insulated battery box (almost independent of outside temperature) takes 3 hours, and the aluminum plate never gets about about 75°F. I've logged and plotted it all and posted it here.

100 Proof

"Please Lord, don't let me do something stupid."

- Joined

- Feb 14, 2021

- Messages

- 206

Just to put a bow on my cell heating system performance for those reading this thread in the future, the aluminum plate in my cell heater system transfers heat REALLY WELL into the cells. It's hard to measure with everything assembled, but I do not believe my aluminum plate gets even 10 degrees F above cell temp. So at my target heater shut-off temperature of 44 degrees F, the plate would be below 54 degrees F.

BOTTOM LINE: I've been pleased with the system performance this winter and would do it the same way again.

BOTTOM LINE: I've been pleased with the system performance this winter and would do it the same way again.

Similar threads

- Replies

- 5

- Views

- 564

- Replies

- 9

- Views

- 2K

- Replies

- 29

- Views

- 695