Yes, case needs to be grounded.

For my Sunny Island, there is a "PE" terminal on the PCB, that grounding conductor is fastened to.

The construction of the inverter takes care of connecting that net to enclosure. I don't have to run a separate wire to the enclosure.

The pictures posted here, I think of the GroWatt, have a grounding screw removed but I'm not clear from the board markings that is the neutral/ground bond, or the case/ground bond. Case grounding is normally tested for several 10 seconds with 10A AC, looking for < 0.1 ohms (or similar figures, I don't remember exactly). This would confirm a solid connection.

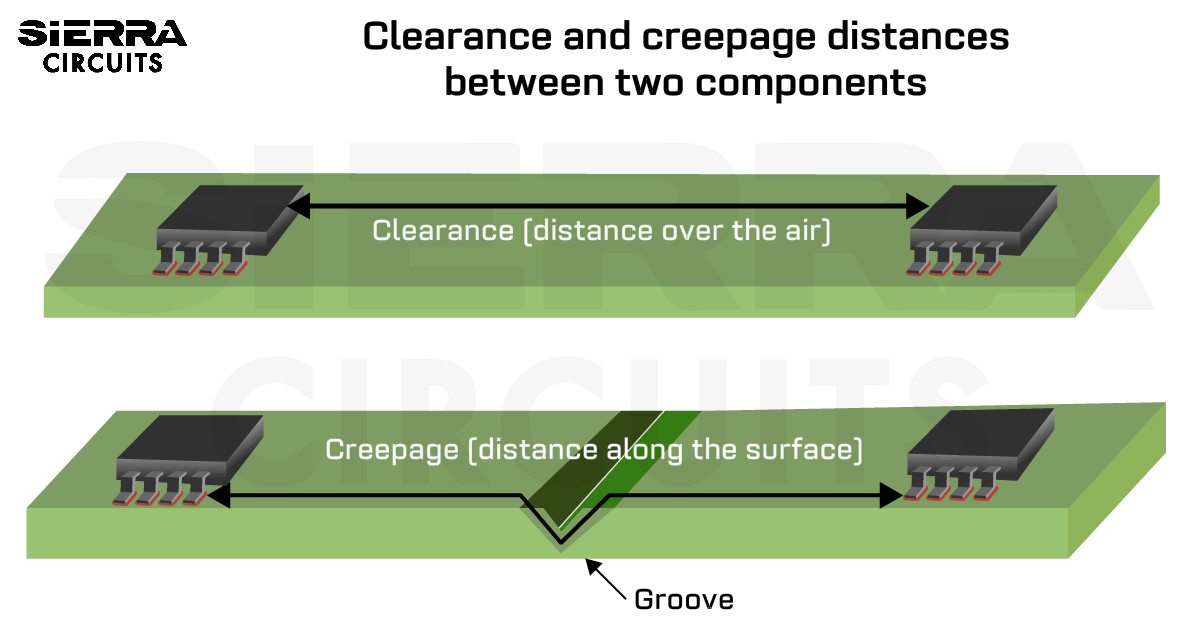

Isolating Neutral/Ground at the inverter is probably the thing to do when Neutral/Ground bond occurs at the utility entrance. And then very low voltage between them at he inverter, so not concerned about creepage/clearance. If "Neutral" becomes "Line2" in a split-phase configuration, then it has to withstand line voltage across it so those dimensions do matter.

View attachment 80175

Yes, when powered.

With all sources of power disconnected, a little experiment could check if isolation between "Neutral" (which is now repurposed as "Line2" and chassis can make contact. Ohm meter and pushing on PCB.

If you ship me one I'd be happy to try it out. And other things too. I'm a "Qualified Electrical Worker"