Dustin Henderson

New Member

- Joined

- Nov 2, 2022

- Messages

- 17

I have a RV trailer on which I am going to add a modest solar set up for the purpose of recharging the LifePO4 on board battery for the occasional day or two of boon-docking. Most of my time is spent on FHU, but sometimes we have an over night stop without power, or a weekend in the forest (where I use a portable panel and run the generator for A/C and when needed). I have a 100Ah battery which has never presented a problem because of our minimal use, but I do worry I might run out of juice to power the landing gear or slides or lighting or furnace fan which would force me to fire up the Honda (not a big deal) on a quick overnight.

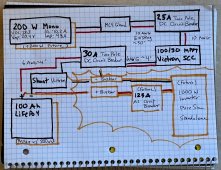

So, I am going to install a couple hundred watts on the roof. I am going to start with a single 200 Watt panel (eg Rich Solar). I will wire in a Victron SmartSolar MPPT 100/30 because I like the bluetooth and app interface and hear good feedback and don't mind the premium over a budget controller. I will add a shunt or appropriate battery monitor. The trailer is wired for solar (10 AWG?)with MC4 connectors up top. I plan to put the SCC somewhere near the battery rather than inside. Hope I can find the wires …

Future Considerations: This trailer is not my long term RV, and I will never be integrating an inverter in to the core electrical system. However, I could envision going to 200+ Ah of battery, and I probably envision adding another 200 W panel (maybe sooner than later on that one. There is not a ton of convenient space for more so 400 is probably the max, or maybe 600. I may at some point choose to put a small/cheap 1000W inverter in for charging purposes and occasional plug in of light loads, but not wired in to the RV electrical.

Questions that come to mind:

Is the panel I speced out* sufficient to meet the draw demands required to kick off the MPPT? I am looking for higher VOC panels to make sure I have head room.

When I add another panel, I assume I may want to go parallel (depending on answer above) because shading and the flat panel placement are not ideal. Does that make sense? If going serial I think the MPPT still has plenty of room to handle another panel.

Where do I need to put fuses? What types of fuses?

Where to add cut off switches? I have only added one to my battery for a true battery cut off. I presume I want another one (two?)

What cabling specs are needed and where given my modest future considerations?. Again, this is prewired by go solar and I think they are all awg10. I am not going to pull new cable for this little system.

Thanks for any help.

*Rich Solar 200W

So, I am going to install a couple hundred watts on the roof. I am going to start with a single 200 Watt panel (eg Rich Solar). I will wire in a Victron SmartSolar MPPT 100/30 because I like the bluetooth and app interface and hear good feedback and don't mind the premium over a budget controller. I will add a shunt or appropriate battery monitor. The trailer is wired for solar (10 AWG?)with MC4 connectors up top. I plan to put the SCC somewhere near the battery rather than inside. Hope I can find the wires …

Future Considerations: This trailer is not my long term RV, and I will never be integrating an inverter in to the core electrical system. However, I could envision going to 200+ Ah of battery, and I probably envision adding another 200 W panel (maybe sooner than later on that one. There is not a ton of convenient space for more so 400 is probably the max, or maybe 600. I may at some point choose to put a small/cheap 1000W inverter in for charging purposes and occasional plug in of light loads, but not wired in to the RV electrical.

Questions that come to mind:

Is the panel I speced out* sufficient to meet the draw demands required to kick off the MPPT? I am looking for higher VOC panels to make sure I have head room.

When I add another panel, I assume I may want to go parallel (depending on answer above) because shading and the flat panel placement are not ideal. Does that make sense? If going serial I think the MPPT still has plenty of room to handle another panel.

Where do I need to put fuses? What types of fuses?

Where to add cut off switches? I have only added one to my battery for a true battery cut off. I presume I want another one (two?)

What cabling specs are needed and where given my modest future considerations?. Again, this is prewired by go solar and I think they are all awg10. I am not going to pull new cable for this little system.

Thanks for any help.

*Rich Solar 200W

- Maximum Power(Pmax): 200W

- Maximum Power Voltage(Vmp): 20.4V

- Maximum Power Current(Imp): 9.80A

- Open Circuit Voltage(Voc): 24.3V

- Short Circuit Current(Isc): 10.2A

- Maximum System Voltage(Vmax): 1000VDC

- Temperature Range: -40°C ~ 90°C

- Max Series Fuse Rating: 20A

- Weight: 26.5 lbs