Bossrox

Solar tinkerer

I know many are happy with their victrons but here's details on the trouble I've had with them. It seems they may be cheapening their quality & depending on their reputation to stay afloat. 4 charger failures.

Victron wants you to use many stranded wires, not ferells according to their bigger SCC manualneed to be using ferrells

Do you know what a ferrule is? It is a cover that surrounds fine strand cable ends to allow easy reinsertion, and tidy strand protection.I’m a bit skeptical. I did not watch the whole video. Bringing the item up on Amazon had a couple of complaints that the vendor provided a lesser model, the 85 amp version, and claimed false advertising. I suspect this could be on the vendor not victron. More than likely, this is a different vendor.

I would like to see the whole setup before condemning Victron, so until then I’m skeptical.

I consider the MPPT SCCs Victron’s flagship product, and I have no complaints about the 100/50/, 100/30, And 75/15 I own.

Some of the other accessories are not quite what I consider built to the same standards. Some of the other items like the Orion 70 amp converter I own are lacking in documentation and I would like to see a couple of design improvements, but still better than anything else I found. Another converter they sell looks like a direct copy of what you can purchase elsewhere, with the same specs, except the casing color was changed To VictronBlue and their logo added.

Victron wants you to use many stranded wires, not ferells according to their bigger SCC manual

View attachment 91464

I thought the three images were showing how flexible they wanted the wire to be, thereby reducing strain on the terminals. The images having nothing to do with ferrules. If this is correct, I wonder about the wire type differences in the center and right image. Wire on right even more flexible than the center wire? Wire on right less likely than the center wire to have stray strands if a ferrule isn't used? Wild guesses.Do you know what a ferrule is? It is a cover that surrounds fine strand cable ends to allow easy reinsertion, and tidy strand protection.

Intent is to have the wire crushed as flat as possible for good contact area, which is not what a ferrule is intended to do. This is the rest of what victron says in the larger MPPT manual:Do you know what a ferrule is? It is a cover that surrounds fine strand cable ends to allow easy reinsertion, and tidy strand protection.

The GW look to be a SC 4860 which are 150VOC. Same as the Victron. https://growattinverters.com/Off-Grid-Storage-Inverters/44-613.htmlBoom roasted

“There’s nothing wrong with this wiring”

My best guess is VOC, those growatt are what 250v? Vs 150v of those victrons.

Please expand upon your PV array with specs and how many panels is series and parallel. Not quite clear here: https://diysolarforum.com/threads/j...-to-replace-failed-victrons.34647/post-433211I know many are happy with their victrons but here's details on the trouble I've had with them. It seems they may be cheapening their quality & depending on their reputation to stay afloat. 4 charger failures.

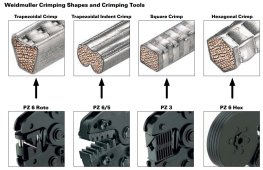

On large cables such as #2AWG a ferrule is not crimped ahead of time, the cable ferrule combo is inserted uncrimped, and the lug crushes the cable properly.A fine strand conductor, is always better.

A ferrule, makes it convenient for re inserting multiple times.

But, it does make a less conductive connection.

(Depending on the type of terminal)

Terminals with a round opening, and a set screw. Don't lose as much surface area contact, with a ferrule.

Square type Terminals, with a clamping type connection. Lose a lot of surface area contact, with a ferrule.

So, you have to decide between the best possible connection, and convenience.