I wrote to Midnight about polarity of breakers for an SCC. Here was their response:

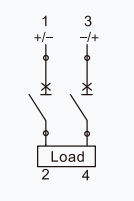

"On the MNEPV Circuit breakers the (+) on the PV IN for the Classic goes to

the PV array positive. The (+) on the battery out breaker of the Classic

goes to the Battery. The 60 or so volts on the battery side have little or

no arc to extinguish. On the PV side we mostly are concerned with

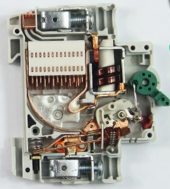

extinguishing the arc when the circuit breaker is manually turn off for

maintenance. If there is a catastrophic event in the PV array they causes

backwards current flow to trip the PV IN Breaker you are going to having

bigger issues than a burned up PV in breaker."

But once I assemble PV array, it can never produce more than Isc (plus a bit for extra illumination from clouds), so oriented to interrupt current from PV panels, it'll never experience overload that way.

Fuses or breakers on PV panels are for protection against backfeed. If I have 6 PV strings in parallel, all producing 7A and each protected with 15A breakers, the fault to consider is a short within one string (which could be diodes failed shorted.) In that case, 5 x 7A = 35A flows backwards into the array.

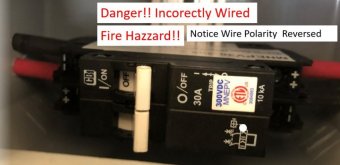

If you manually turn breaker off for maintenance (as Midnight mentions), and current is flowing when you do so, that's the situation where they had a failure on their first attempt because it was backwards (carrying 150% of rated current.) Orienting the breaker per their recommendations allows hot switching to be reliable.

However, interrupting current backfed into one string, which is why OCP is required for 3 or more parallel strings, it isn't going to work.

I believe a solution could be to orient breakers for protection against backfeed into array. And never hot-switch them; turn off charge controller first. Disconnecting from battery could be the way, BUT, some charge controllers may not want PV connected and batteries disconnected.

AND, that breaker between battery and charge controller is oriented to interrupt current backfeeding into charge controller from battery. If you open the breaker while high charge current is flowing, that direction doesn't work well for the breaker. (However, Midnight indicated the ~ 60Voc at battery wasn't such a big problem for arcing. And of course when opened with charge current, voltage from charge controller wasn't much higher than battery. Inductive kick from MPPT might arc briefly but would stop; the kick is more of a problem for MPPT electronics than the breaker.)

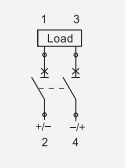

You could use a 2-pole breaker between charge controller and battery, wired so one has the correct direction of current flow for its arc chute. And each pole is rated for full voltage of battery. That would ensure arc in either direction could be extinguished.

The saving grace for my system is that the PV breaker is ganged 6 pole. If I connect per Midnight's recommendation, arc chute works when opened during charging. In the event of a short in one string, that breaker opens due to overload. While it's arc chute doesn't work, the other 5 ganged breakers also open and each successfully interrupts its current (those aren't even overloaded, rather carrying 50% of rating.)