Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,636

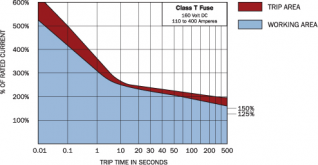

Did you say the short occurred through the fuse? Presumably something like class T?

The 17 milliohm cell internal resistance suggests to me about 22kA, so with class T rated 20kA I would expect it to interrupt successfully.

How long was current flowing? You didn't mention having to use a crowbar to remove the offending metal.

If current only flowed momentarily I have a hard time believing any internal damage occurred, just scorched outside due to arc, splatter, etc.

As Luthj said, takes time to cause enough heat (spread over internal mass)

Other people have had warm busbars at moderate current due to poor contact. I think you just did that with higher I^R

It should have simply blown the fuse, no harm, no foul other than your wrench. But you had a weaker link.

The melted cell terminal looks a bit more aggressive than the process of intentionally welding bars on terminals, could have overheated it enough to damage battery internally near the terminal.

I'm betting that any cell without such terminal damage will just shrug it off.

The 17 milliohm cell internal resistance suggests to me about 22kA, so with class T rated 20kA I would expect it to interrupt successfully.

How long was current flowing? You didn't mention having to use a crowbar to remove the offending metal.

If current only flowed momentarily I have a hard time believing any internal damage occurred, just scorched outside due to arc, splatter, etc.

As Luthj said, takes time to cause enough heat (spread over internal mass)

Other people have had warm busbars at moderate current due to poor contact. I think you just did that with higher I^R

It should have simply blown the fuse, no harm, no foul other than your wrench. But you had a weaker link.

The melted cell terminal looks a bit more aggressive than the process of intentionally welding bars on terminals, could have overheated it enough to damage battery internally near the terminal.

I'm betting that any cell without such terminal damage will just shrug it off.