I would be worried about he nut getting JB Welded in place. Even if surface is cleaned off first, tightening the nut (which may be an unnecessary step) could extrude some.

There are a few options to avoid that, including use of a short 3/8” tube covered by a washer before I thread the nut.

The safe thing to do would be to tighten enough to squeeze out any JB Weld (though if the grubscrew rises, sucking some more JB Weld down seems more likely), remove everything to inspect before it has hardened, clean up anything that needs it, and then either leave it alone or reassemble whatever structure and retighten.

I’m also not terribly worried about a bit of excess hardened JB Weld around the base of the threads - if it’s enough to interfere with a lug, removing with a Dremel shouldn’t be a big deal...

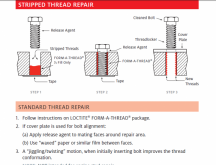

Waxed paper punched over the stud, some sort of release like oil on the threads (the thread repair kits include or recommend a release substance).

Maybe put a (non threaded) standoff over the stud against waxed paper, and a nut to clamp it. No intimate contact with terminal or thread near terminal, avoiding contact with epoxy. Large enough diameter standoff and a washer for the nut, no need for waxed paper or other release material.

I’m not too worried about the thread - between lug, washer, and locknut, there will be done distance above the terminal surface before the threads are engaged by the nut.

Avoiding JB Weld between the lug and the terminal surface is my primary concern. Avoiding hardened JB Weld around the post near the terminal surface which interferes with the lug is my secondary concern, but again, some time with an appropriate dremel grinder should quickly resolve that...

When using urethane glue to put down tongue and groove flooring, I clamped the boards with straps. Last board would always buckle upward, so one extra board without glue. To prevent it from bonding to the last glued down board, a sheet of waxed paper folded over the edge. Hand lotion was my way to avoid gluing my fingers in the process.

Good idea, but hopefully this proves to be an easier problem.

My greatest concern, frankly, is trying to go too fast. Trying to use one batch of JB Weld to glue in several posts could result in a big mess. So this first go-round, I’ll only focus on that one single post on that one single (partially-stripped) thread and then I’ll see how long the remaining JB Weld remains workable.

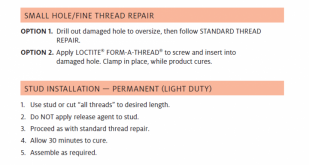

I’m pretty confident I’ll be able to get that one post successfully glued-in with JB Weld - it just may be such a PITA that I want to switch to Loctite Red for the remaining 31 studs (I have a total of 16 cells for two 8S batteries).