I would think about safety, security & reliability.

1) If you have ONE huge Battery and something goes wrong, that's it, you only have the one. Remember Murphy's Laws Apply :

"Anything that can go wrong will go wrong and at the worst possible time."

2) Paralleling 2 or more battery packs provides redundancy, they will share/split charge & load thereby reducing stress potential.

3) Keep It Simple & Serviceable (KISS), don't build a battery with Paralleled cells, stick to a simple Series Configuration.

4) Make sure all wiring and components are Marine Grade, so use tinned lugs, cables, etc., and properly crimped with high-grade shrink tube with adhesive !

5) When locating the battery assembly, make sure it is "high & dry" and the batteries are secured (water tight is best).

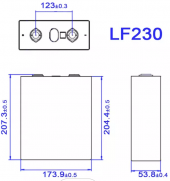

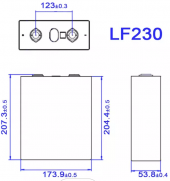

NOTE: BEFORE Purchasing cells, look at the Specs, particularly the physical size of the cells, they all vary depending on Manufacturer & AH Capacity. Know how much space you can allocate, not only for the cells but the BMS and the casing for each.

Special Note !! Do NOT use Very Large Cells ! they are intended more for static placement like a home ESS and not for mobile (especially rough) use. IF you are DIY'ing the batteries, then have a "spare BMS", fuses etc on hand (see murphy's laws). You can buy Battery Boxes or build your own but the ABS Plastic Boxes are likely most suitable for Marine use, see link below for example.

Grade-A Matched & Batched cells with test report from EVE from this link suggested.

1pcs Eve 230ah Lifepo4 (lfp) 3.2v Cells Battery (new Version,Fully Matched And Batched)--genuine Grade A - Buy Eve,Lifepo4,Rechargeable Battery Product on Alibaba.com

www.alibaba.com

ABS Waterproof Box:

https://www.alibaba.com/product-det...terproof-Battery-Box-Case_1600553604483.html?

Suggested BMS: JK(jikong) 2A Active Balance Smart BMS for 4-8S 12V PN:

JK-B2A4S20P

A resource to download which you will find handy on Battery Assembly and more:

This document was posted to the forum by Amy from Shenzhen Luyuan and written by Steve S. It was meant to be posted as a resource. Below is her description of the resource: Dear all friends in the forum, This file in the attachment was...

diysolarforum.com

Hope it helps, Good Luck.