Rocksnsalt

Solar Enthusiast

It’s true!

Yes, external regulator. I'm pretty sure all of the aux alternator products use external regulators for control purposes, charge profiles and the like. Balmar has the lion's share of the market, but Wakespeed is now coming up to speed (so to speak) as well. Wakespeed indeed designed their suite of products for the marine world, but they work great in RVs, particularly for lithium systems.To be clear, you are talking about using an external regulator with your aux alternator, yeah?

This was not clear from the first couple comments in this thread.

How has that been working for you? Its a solution that seems more popular in the marine world, haven't heard many first hand experiences installing/using an external regulator for vehicle applications, and I'm quite curious about it. How was the difficulty of install/setup? What sort of charge current do you see? Biggest downsides?

It’s ok, these are your people to talk that stuff to.Yes, external regulator. I'm pretty sure all of the aux alternator products use external regulators for control purposes, charge profiles and the like. Balmar has the lion's share of the market, but Wakespeed is now coming up to speed (so to speak) as well. Wakespeed indeed designed their suite of products for the marine world, but they work great in RVs, particularly for lithium systems.

My system has a DIY battery based on Fortune cells (thanks, Will), Wakespeed regulator and REC BMS. The BMS is connected to the regulator via a CANbus. The BMS actually controls charging based on its fine-grain visibility into what the cells are doing, and sends current requests to the Wakespeed which in turns sends exactly that much current to the battery. They call this a remote-battery-master configuration. There's no charge profile because the regulator is simply doing what the BMS tells it to do. The BMS has settings for battery size and your desired C rate which it uses in conjunction with cell voltages to calculate how much current to request. Usually it's requesting your full desired C rate until it's full. So with my 200 AH battery, I'm generally charging at around 100 amps. I will be adding another 8 cells to for 400 amps total. I'll only need to change the battery size parameter and I'll be charging at 200 amps with no other changes.

I was an early adopter of this technology for use in a van and pretty bullish on it. The install is actually pretty easy and logical and nothing that anyone who works on charging systems can't handle. Setup is easy too. As an early adopter, I had some bugs bringing up the system that were worked around in firmware by Wakespeed. But the system is rock solid now and should work for anyone else right out of the gate.

Sorry, I get carried away talking about this stuff. I have a build thread about it on the Sprinter forum here. https://sprinter-source.com/forums/index.php?threads/89088/

You do not use a B2B (DC-DC) for an aux alternator, you wire it direct. My aux alternator puts out 280 amps all of which is usable for charging. So a 206AH battery that charges at only a 0.25C rate is inadequate for me because I can charge a decent battery twice as fast.

a single SOK 206 will not work for me, and I would not recommend it for a vanlife person,

especially if they need more than a paltry 0.25C charge rate.

Thanks!Welcome to the forum. I think you'll fit right in.

I don't understand your question about idling. I charge whenever the battery is below 100% and the engine is running, and it's generally charging at my preferred 0.5C. Once I populate the rest of my cells and increase my battery to 400 AH then there will be some roll-off of current at idle. Although I've already seen it put out around 150 amps at idle, so not much degradation. The van is diesel, btw, and idling for extended periods is bad for them.Are you idling to recharge? If so, faster charging does makes sense as one can reduce time idling the engine.

If one doesn't have time pressure (driving from place to place, or maybe solar is helping out) I'd think the lower 0.25C rate would be gentler on the batteries than 0.5C, especially in colder temperatures.

If vanlife means Instagram hashtag-vanlife with apartment-style amenities then I agree. If it means people who live in vans in my experience meeting a few hundred vandwellers over the past few years I'd say the majority (or at least plurality) are using solar to recharge ≤200Ah lead banks. Those folks would likely be delighted with the smaller SOK 100Ah.

My fulltime boondocking use case: maximum load is ~300w, typical loads ~150w, all loads run off solar in the daytime, and I use 30-40Ah overnight. For me a SOK 206Ah would be overkill and unnecessary expense.Horses for courses, as they say.

0.25C is paltry compared to your charging capacity, but not paltry for LFP in general. I'd be surprised if the typical member of this (admittedly solar-centric) forum was charging lithium at ≥0.25C. I have 750w of solar charging a 100Ah LFP and under normal conditions it charges at less than 0.25C.

And 48v/12kwh systems that can run ac all night… Having and 800amp alternator helps for a quick charge… as theyThanks!

I don't understand your question about idling. I charge whenever the battery is below 100% and the engine is running, and it's generally charging at my preferred 0.5C. Once I populate the rest of my cells and increase my battery to 400 AH then there will be some roll-off of current at idle. Although I've already seen it put out around 150 amps at idle, so not much degradation. The van is diesel, btw, and idling for extended periods is bad for them.

I'm not aware of any downside to charging at 0.5C. The batteries can handle 1C, so 0.5C is already conservative. If you have references to such information, I'm all ears. My batteries are always warm because they live inside the van. The BMS is temperature savvy, so if there were temperature ranges that needed less current then it would call for less power. It does kill the power at low temps close to freezing, as those charging at those temps can damage the battery.

Ha, you should check out the Sprinter forum. We have guys there with 1100 AH lithium batteries running AC all day. I'm more towards your camp, but I like hot food and hot coffee and my heated mattress pad in the winter.

And 48v/12kwh systems that can run ac all night… Having and 800amp alternator helps for a quick charge… as they

(Storyteller Overland Vans) only have a token 100w of solar, but room for 300 to 400w more if they give up the rooftop deck space. That would be me, given the choice.

I believe they are just asking whether you idle the van to charge the batteries (i.e. use the van as a big inefficient generator) as opposed to just taking advantage of charging when driving.Thanks!

I don't understand your question about idling.

There is a three way relationship between temperature, c-rate, and state of charge. Or to simplify it a bit a two way relationship between temperature and c-rate. A certain C-rate will cause more wear and tear on the battery at a low temperature than it will at a moderate temperature, or put another way charging at a low c-rate at a low temperature is less bad than charging at a high c-rate and low temperature, this is more pronounced at higher states of charge.I charge whenever the battery is below 100% and the engine is running, and it's generally charging at my preferred 0.5C. Once I populate the rest of my cells and increase my battery to 400 AH then there will be some roll-off of current at idle. Although I've already seen it put out around 150 amps at idle, so not much degradation. The van is diesel, btw, and idling for extended periods is bad for them.

I'm not aware of any downside to charging at 0.5C. The batteries can handle 1C, so 0.5C is already conservative. If you have references to such information, I'm all ears. My batteries are always warm because they live inside the van. The BMS is temperature savvy, so if there were temperature ranges that needed less current then it would call for less power. It does kill the power at low temps close to freezing, as those charging at those temps can damage the battery.

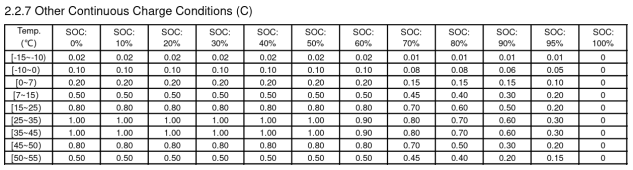

There is a three way relationship between temperature, c-rate, and state of charge. Or to simplify it a bit a two way relationship between temperature and c-rate. A certain C-rate will cause more wear and tear on the battery at a low temperature than it will at a moderate temperature, or put another way charging at a low c-rate at a low temperature is less bad than charging at a high c-rate and low temperature, this is more pronounced at higher states of charge.

There are some high temperature considerations as well.

The fact that the batteries can handle 1C doesn't necessarily make 0.5C conservative, but it does mean it is well within spec. If your cells can handle a max continuous charge rate of 1C, its likely the manufacturer recommends 0.5C as the max recommended charge rate, depends on the manufacturer but that is a pretty standard recommendation. None of this is meant to imply that your 0.5C charging target is unreasonable or unrealistic or wrong, just that it is about the upper edge of the range of what many people here consider to be conservative.

|

Frey (the company that manufacturers the cells ECPC sells under the name "Fortune") makes really solid cells from everything I've heard, and I have heard they are a little more geared towards power rather than energy storage applications (IIRC electric forklift batteries may have been one of their original markets). Generalizations made about the larger cheaper commodity prismatic cells popular here may not always apply to your cells, and likewise, things that apply to your cells may not always apply to larger form factor prismatics.Maybe I misspoke about the 1C max charge rate. I'm using Fortune cells and went back to look at their specs to refresh my memory. What I went by is what they call, "Standard Charge Current" which is 0.5C. They don't actually give a max charge rate except for a "Max Pulse Charge Current (<10 sec)" which is 6C. I'm used to seeing the 1C maximum charge rate quoted by other people that apparently I assumed mine was the same.

Here's the link to their specs: https://www.electriccarpartscompany.com/fortune-100ah-aluminum-encased-battery

You left off the less than sign, the spec in the link says "Best charging current <0.5C" further you can see a few lines above that the cycle life estimates are based on 0.2CHere's a spec to another 100 AH prismatic cell and they give a "Best Charging Current" of 0.5C. https://www.batteryspace.com/lifemn...3-2v-100ah-3c-rate-320wh---un38-3-passed.aspx

Note that their Max Charge Current is 3C.

None of this is meant to imply that your 0.5C charging target is unreasonable or unrealistic or wrong, just that it is about the upper edge of the range of what many people here consider to be conservative.

'harm' isn't the term I would choose to use. I'd think of it more like a rate of degradation. There isn't a magic number below which you are fine and above which you are not (even if we leave out context/other variables). I think of it more like a gradient/spectrum of wear and tear, you are not 'harming' your batteries by cycling at 0.5C, but capacity loss/degradation will likely be faster than it would be at 0.25C and slower than it would be at 1C. In normal operation 0.5C may be at the upper edge of the 'sweet spot' but in colder weather or high SOC 0.5C would exceed manufacturer recc's for many cells. Here is an example from the 206Ah Ganfeng datasheet (what SOK uses in their batteries):So I doubt I'm doing any harm at 0.5C

Lithium plating is a phenomenon that deserves its own paragraph because it originates primarily from improper management of the cells. It is very harmful and results in irreversible capacity loss. Lithium plating refers to the formation of solid lithium metal within the cells. Lithium metal forms when the intercalation mechanism of the lithium ions fails to take place normally and solid lithium can be deposited on the surface of the anode or around its edges typically. There are a small number of well-known situations that promote lithium plating:

- Excessive charge rates. If the charge rate exceeds the cathode’s rate of absorption for lithium ions, lithium metal is instead deposited onto the surface of the electrode. Most manufacturers recommend operating the cells at or below 0.3C in spite of much higher charge rates being readily achievable. The most recent generations of cells are rated for sustained operation at up to 0.5C.

- Cold temperature charging. Temperatures close to or below freezing dramatically reduce the absorption rate of lithium ions into the graphite cathode, because lithium insertion becomes more difficult. In other words, charge rates that are acceptable at normal ambient temperatures become excessive in cold conditions.

- Trickle charging. Trickle charging causes all of the lithium present in the cells to be transferred to the positive electrode, whether it can be normally inserted into the carbon cathode or not. Any lithium that cannot be absorbed normally ends up plating the cathode.

From the above, it should be obvious that an operating regime combining fast charges followed by a trickle charging is particularly harmful. A fast charge tends to saturate the anode surface with lithium ions and then any additional charging results in lithium plating. This scenario can quite easily be met on marine installations where a focus was placed on fast recharging through the use of an engine and alternators (or high-capacity DC chargers) and renewable energy systems then fail to properly implement a charge termination and hold the cell voltages up.

I don't understand your question about idling.

I'm not aware of any downside to charging at 0.5C. The batteries can handle 1C, so 0.5C is already conservative. If you have references to such information, I'm all ears.

The BMS is temperature savvy, so if there were temperature ranges that needed less current then it would call for less power.

It does kill the power at low temps close to freezing, as those charging at those temps can damage the battery.

I like hot food and hot coffee and my heated mattress pad in the winter.

Ha, you should check out the Sprinter forum. We have guys there with 1100 AH lithium batteries running AC all day

I was an early adopter of this technology for use in a van

Gotcha. Yeah, idling isn't good for modern diesels so I do it as little as possible. What I like about my fast charging is that I can camp 20 minutes from the ski resort and pretty much generate enough power for 24 hours, especially if I stop at the grocery store.@Dzl covered it, but I will flesh it out a bit to lay out my thinking.

My thinking was that if one is idling the vehicle to charge then a higher charge rate is likely a good economic move. Any theoretically-shorter battery cycle life would be offset by reduced wear/stress on the engine and alternator (auxilliary or otherwise).

Good thoughts. You guys are pretty much convincing me that I definitely don't want to go faster than 0.5C. Ya know, since the C-rate on the BMS is adjustable, I could crank it down when I don't need fast charging. There's actually an app for the BMS, so I can set the charge rate any time. But the wifi is point-to-point, and not as convenient as I like. They have a Bluetooth app which I use all the time but it only monitors and and is unable to set parameters for the most part. Maybe I can cobble up a dedicate device for it. A knob on the dash with an ammeter would be perfect.If one is charging by multiple methods or if normal driving is sufficient to meet needs I am suggesting that lower charge rates increase LFP longevity. I understand this is not a universally-held position. Perhaps I am deluding myself and it is merely a form of Pascal's Wager.

I suspect 0.5C is a compromise between charging speed and longevity. Joe Sixpack wouldn't be happy if his new $1000 battery took 5 hours to charge. OMG, that's like one of those lead-acid plebes!So give them a rate high enough to keep them happy while making it through any warranty period.

I have seen manufacturers give the rated/warranted cycle life at 0.5C then give "and up to..." even higher cycle numbers with an asterisk ("when discharged 80% DoD and charged at 0.2C rates"). This isn't dispositive but it's food for thought.

Even more speculative: Battle Born says "We don’t recommend you exceed this [0.5C] charge rate as it can lead to a shortened battery cycle life." What is more likely, that 0.5C is a hard cutoff beyond which cycles will be reduced, or the top end of a sliding scale? More on this below.

Note: certainly not trying to tell you how to charge your bank. I am talking out loud about the factors that informed my own charging choices.

Well, the BMS in my system does fine-grain control over the charging, not just off and on. It gives a specific current target to the regulator which varies while certain stuff is going on. Cell-balance mode is one of those cases, it backs off the charging by 10 or 20 amps or so. There's probably some technical why they do that, but I don't know why it is. Further the BMS does have a battery temperature control which it uses for hard disconnects if battery temps are too high or too low. It could certainly implement the temperature/charge rate curves you guys are talking about if it doesn't already. The hardware is all there, just a matter of adding firmware.I looked over the the REC ACTIVE manual and website and didn't see any claims that it can regulate charging current from the alt beyond on/off. It was admittedly a cursory reading so maybe I missed something. You will certainly know more about it than I do.

Interesting, thanks. Usually I'm well above 50F since I leave my diesel-fired heater on constantly even when I'm parked in the winter.It appears to be a sliding scale rather than hard cutoff -- see these data sheets.

In the charts the average low temp at which 0.5C is allowed is 9.75C (49.55F) and the mean is 10C (50F). I hope I used those math terms right. The lowest of them is 5C (41F). Lower charging rates are allowed at somewhat lower temps, which might or might not tell us something about charging rates at warmer temps.

I have a nice backpacking stove that would work great. But I'm pretty happy with being all electric, single energy source (except for the diesel fuel my heater consumes).Same. Cooking and making coffee over a $40 stove allows me to run all my loads (including the heated mattress pad) on 100Ah LFP. I do cook with electricity when there is excess solar power available which helps stretch the fuel supply. Right now I am cooking broccoli and cauliflower in a crock pot.

That is awesome. Hats off to you. I retired early myself, although I've still have small business that that makes me money sporadically. I've got a family situation, but even then I managed to put 36K on my van in my first year. My longest trip was 3 weeks and that went great. If it weren't for the wife I might be a full-timer myself.Same on the Promaster and Transit fora. I fully support each vandweller building the rig that meets their particular wants and needs.

My own are minimal since there is no Wife Acceptance Factor and I follow mild weather. Once I had the van my total build cost was about $2250. I've been boondocking off-grid in it for the last (...checking...) 1,214 days. This low-cost approach allowed me to retire about 8 years early, so doggo and I are quite happy.

Early adopters were DIYing LiFePO4 in vans by 2014-2015 (example), leveraging information from the boating world that started showing up in 2010-2011. In those days many people were running LFP "barefoot" because the BMS were so crude they were doing more harm than good. I am grateful the technology has advanced and come down in price.

Thank you for your thoughtful input.

That is great to know, thanks. I love the build quality on them, the huge M10 terminal studs and the end caps with threaded rod holes, and the top caps to protect the terminals and bus bars. Plus there are built-in wire troughs to keep things tidy.Frey (the company that manufacturers the cells ECPC sells under the name "Fortune") makes really solid cells from everything I've heard, and I have heard they are a little more geared towards power rather than energy storage applications (IIRC electric forklift batteries may have been one of their original markets). Generalizations made about the larger cheaper commodity prismatic cells popular here may not always apply to your cells, and likewise, things that apply to your cells may not always apply to larger form factor prismatics.

You've got good robust cells and a nice BMS (that can apparently taper current when it sees fit), and you are within the manufacturer recommendations for your cells, I don't think you have much to worry about.

Oops, my bad. I missed that.You left off the less than sign, the spec in the link says "Best charging current <0.5C" further you can see a few lines above that the cycle life estimates are based on 0.2C

Which is inline with what I was attempting to articulate in my previous comment:

But we don't need to get into the weeds here. Different cells will have slight differences, and some will be better optimized for power (high c rates) while others (particularly the larger cells popular right now) will often be more optimized for energy storage and cost. Also different manufacturers will be more or less conservative in their recommendations and cycle life estimates. As a generalization lower c-rates are less taxing, this particularly comes into play at low temp, high SOC or both.

'harm' isn't the term I would choose to use. I'd think of it more like a rate of degradation. There isn't a magic number below which you are fine and above which you are not (even if we leave out context/other variables). I think of it more like a gradient/spectrum of wear and tear, you are not 'harming' your batteries by cycling at 0.5C, but capacity loss/degradation will likely be faster than it would be at 0.25C and slower than it would be at 1C. In normal operation 0.5C may be at the upper edge of the 'sweet spot' but in colder weather or high SOC 0.5C would exceed manufacturer recc's for many cells. Here is an example from the 206Ah Ganfeng datasheet (what SOK uses in their batteries):

View attachment 75379

Bottom line, stay within the manufacturer recommended specs, and you should be fine, go beyond that (more conservative) and you should be extra fine.

That is very cool. Thank you for the gentle correction.the BMS in my system does fine-grain control over the charging, not just off and on. It gives a specific current target to the regulator which varies while certain stuff is going on. Cell-balance mode is one of those cases, it backs off the charging by 10 or 20 amps or so.

You don't need to put anymore solar on that Storyteller van since the alternator can charge it in very little time. That's the whole idea about putting a huge dedicated 48V alternator in them.And 48v/12kwh systems that can run ac all night… Having and 800amp alternator helps for a quick charge… as they

(Storyteller Overland Vans) only have a token 100w of solar, but room for 300 to 400w more if they give up the rooftop deck space. That would be me, given the choice.

Thanks for the elucidation.You don't need to put anymore solar on that Storyteller van since the alternator can charge it in very little time. That's the whole idea about putting a huge dedicated 48V alternator in them.

My friend has the Metro ordered. He should get it in April. He as ZERO plans of adding more solar. Makes no sense.800 amp alternator. Yes that’s true. I don’t have a STO yet so it’s not an issue for me yet. ?