AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

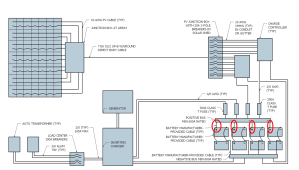

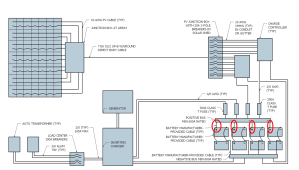

We've seen it done both ways, the Pylontech manual says protection is required between the batteries and the inverter which, I suppose, this design does but many people seem to think fusing or breakers should be put on the Pylontech battery cables before the bus bar and as close to the batteries as possible (any closer than about 6.5 feet would require us to cut the supplied Pylontech cables to make that happen since the supplied Pylontech cables are 6.5 feet long). The consultant we hired thinks we should do it like this instead without that protection. He says:

Is he right, or should we put 125A fusing or breakers (since the Pylontech cables are rated to 125A max) between the Pylontech battery cables and the bus bar in addition to the t-fuses he has shown?

This is his design of our system.

As discussed the battery cables connecting to the bus bar have the concerning source of power at the batteries. Thus, unless you can mount the 125A class T fuse you mention right at each battery, there is no point in protecting this wire run. If the class T fuse is at the bus bar, it only protects the bus bar, which does not need protection. The best place for the class T fuses in this installation is as shown - protecting the cables that connect equipment from the high current possible from the batteries. Keeping the battery lead cables short is the most important concern that you have already addressed.

Is he right, or should we put 125A fusing or breakers (since the Pylontech cables are rated to 125A max) between the Pylontech battery cables and the bus bar in addition to the t-fuses he has shown?

This is his design of our system.

Last edited: