Aakelley

New Member

- Joined

- Feb 3, 2022

- Messages

- 140

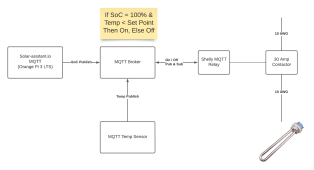

I am a few weeks away from adding another 1kw in panels to my mobile system, which will give me 2.6kw total. I will wait to see what the system production looks like once everything is in place, but there have already been a few days where I am generating more energy than my batteries (10kwh of LifePO4) can absorb. Of course there are many days where that is not the case, hence the additional panels ;-).

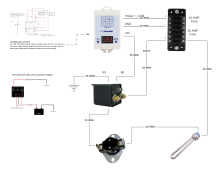

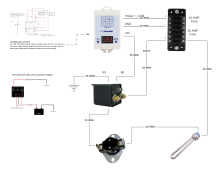

In anticipation of wanting a diversion load, I have been playing around with converting my small hot water heater to run on DC and front ending the circuit with a voltage sensitive relay that would kick on when batteries are nearing 100% SoC voltage and send power through a high amp relay to a DC heating element (swap out the AC one that's in there presently). Sharing out to see if there is anything I might be missing or any better part suggestions?

Parts I plan to use:

In anticipation of wanting a diversion load, I have been playing around with converting my small hot water heater to run on DC and front ending the circuit with a voltage sensitive relay that would kick on when batteries are nearing 100% SoC voltage and send power through a high amp relay to a DC heating element (swap out the AC one that's in there presently). Sharing out to see if there is anything I might be missing or any better part suggestions?

Parts I plan to use:

- Voltage sensitive relay: https://www.bimblesolar.com/digital-voltage-relay

- High Amp relay: https://www.amazon.com/gp/product/B07T48QKQB/ref=ewc_pr_img_1?smid=A1M1RWN6HRL8BC&psc=1

- DC Thermostat: https://windandsolar.com/water-heater-thermostat/

- 24V 600W heating element: https://www.amazon.com/gp/product/B01CNMI66M/ref=ewc_pr_img_2?smid=A3TV5NVFP7DUSD&psc=1