Forester

New Member

- Joined

- Aug 14, 2020

- Messages

- 8

Hey guys!

My head is about to blow up from all the math, amps, watts, volts... Please help me to understand how to size a system which would be used in an off grid cabin, living there full time. I'm still in the phase where I'm trying to figure out the costs of moving into the sticks and going off grid full time so I just need to do a rough estimation of costs. Obviously, I need to get the numbers right in order to have that estimate and I hope someone can help me out.There's a ton of explanations and videos online and it's often somewhat contradictory and confusing. So far I think I have been able to get a few things correctly, so let's start with that.

Every of those "how to" articles and videos agree on one thing and that's you need to know your daily consumption. So in my case, a rough estimate would be:

1.Fridge 640w/day (A++ rating, almost the best there is. Might be different than in the States but that's how energy efficiency is marked in Europe)

2.Freezer 575w/day, also A++

3.Water pump 370w/day

4.Mini washing machine 210W/cycle ( this is a bit confusing as it wouldn't be used on daily basis, more like once or twice a week. As it's just 210W I thought I could just cout it as it would be used every day and have those 210w extra for some odd, short usage of stuff like blender or something similar)

5.Laptop 280w/day

6. LED light bulbs 240w/day

Water heater and oven would be running on LPG. So this comes to 2315w, guess it can be rounded up to 2.4Kw

Now the rest is unclear. Some move on by calculating what battery size is needed for that much of Kw, which makes sense to me. They say discharge shouldn't be more than 50% for flooded batteries(can't afford Li) and few days of autonomy should be accounted for. As I'm on a budget, I added 1.5 days for that.

Hence it's 2400w x 1.5(to account for that 50%) x 1.5(days of autonomy) = 5400w

Then what comes next is, according to those instructions, to get total amps of the batteries needed, so 5400w/12v=450A

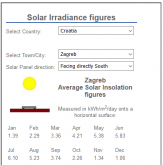

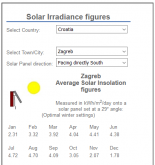

And then to figure out how many panels you need, 5400w/5 hours on average of peek sunlight = 1080w, guess we can round that up to 1.2Kw

Logically, this seems to be correct so far.

But is it??

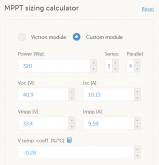

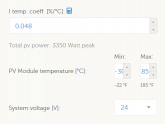

It gets confusing when it comes to the controller. I read that MPPT are better so I'd go with that one but I'm not sure how to calculate it. One article said you just need to divide wattage of panels with volts(battery volts??) So it would be 1200/12= 100A, but that seems too much. If 1200/24= 50A, it sound like it could be correct as I've seen those controllers in 50&60A size, but not in 100A.

But this is confusing, are volts here those coming of the panels or it's related to the batteries?

The last one, inverter, seems to be quite straightforward if I got it right. They say just take your total consumption(2.4Kw) and, kind of , assume everything will be on at the same time. So with 2.4Kw the inverter would be about 3Kw?? And it should have charging capability, to hook it up with a generator.

Please guys, correct what's wrong and if someone has nothing better to do I'd really appreciate if you could do the whole calculation and wright it down so that I can learn how it's done correctly.

My head is about to blow up from all the math, amps, watts, volts... Please help me to understand how to size a system which would be used in an off grid cabin, living there full time. I'm still in the phase where I'm trying to figure out the costs of moving into the sticks and going off grid full time so I just need to do a rough estimation of costs. Obviously, I need to get the numbers right in order to have that estimate and I hope someone can help me out.There's a ton of explanations and videos online and it's often somewhat contradictory and confusing. So far I think I have been able to get a few things correctly, so let's start with that.

Every of those "how to" articles and videos agree on one thing and that's you need to know your daily consumption. So in my case, a rough estimate would be:

1.Fridge 640w/day (A++ rating, almost the best there is. Might be different than in the States but that's how energy efficiency is marked in Europe)

2.Freezer 575w/day, also A++

3.Water pump 370w/day

4.Mini washing machine 210W/cycle ( this is a bit confusing as it wouldn't be used on daily basis, more like once or twice a week. As it's just 210W I thought I could just cout it as it would be used every day and have those 210w extra for some odd, short usage of stuff like blender or something similar)

5.Laptop 280w/day

6. LED light bulbs 240w/day

Water heater and oven would be running on LPG. So this comes to 2315w, guess it can be rounded up to 2.4Kw

Now the rest is unclear. Some move on by calculating what battery size is needed for that much of Kw, which makes sense to me. They say discharge shouldn't be more than 50% for flooded batteries(can't afford Li) and few days of autonomy should be accounted for. As I'm on a budget, I added 1.5 days for that.

Hence it's 2400w x 1.5(to account for that 50%) x 1.5(days of autonomy) = 5400w

Then what comes next is, according to those instructions, to get total amps of the batteries needed, so 5400w/12v=450A

And then to figure out how many panels you need, 5400w/5 hours on average of peek sunlight = 1080w, guess we can round that up to 1.2Kw

Logically, this seems to be correct so far.

But is it??

It gets confusing when it comes to the controller. I read that MPPT are better so I'd go with that one but I'm not sure how to calculate it. One article said you just need to divide wattage of panels with volts(battery volts??) So it would be 1200/12= 100A, but that seems too much. If 1200/24= 50A, it sound like it could be correct as I've seen those controllers in 50&60A size, but not in 100A.

But this is confusing, are volts here those coming of the panels or it's related to the batteries?

The last one, inverter, seems to be quite straightforward if I got it right. They say just take your total consumption(2.4Kw) and, kind of , assume everything will be on at the same time. So with 2.4Kw the inverter would be about 3Kw?? And it should have charging capability, to hook it up with a generator.

Please guys, correct what's wrong and if someone has nothing better to do I'd really appreciate if you could do the whole calculation and wright it down so that I can learn how it's done correctly.