svetz

Works in theory! Practice? That's something else

Saw this in a post and thought it worth discussion in it's own thread since I suspect UV is one of the main factors that causes solar panels to degrade ~.5%/yr.

Anyone ever try this or know what causes panel degradation (e.g., UVB)?

See also: Water repellent coating for solar panels

... I did consider coating them [flexible panels] with a UV resistant lacquer but never got around to it...

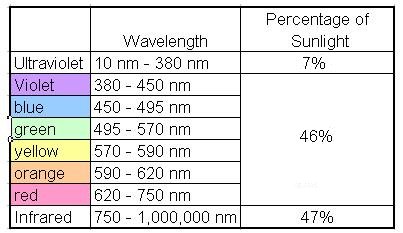

| I use 303 on my plastic Kayak... essentially it's like sunscreen and wears away after a few months. But, it does keep the side facing the sun the same color as the rest of it. The Ceramic car waxes (SiO2) are suppose to do that too. But Solar panels convert UV into power, so putting a UV block on them should rob them of power, how much? Looks like 7% from the image to the right, although probably varies vendor to vendor and the thickness of the coating. Would a thin coating knock enough energy off the damaging UV rays? UVC is completely absorbed by the atmosphere and UVB (280-314nm) is mostly absorbed while UVA (315-399 nm) is not absorbed by the atmosphere. |

Anyone ever try this or know what causes panel degradation (e.g., UVB)?

See also: Water repellent coating for solar panels

Last edited: