You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solar wiring 10x200w panels

- Thread starter TankFish

- Start date

Did you forget the word YOU as you make no senseI think YOU had decided on 12v panels- so a 20v output, but it is always good to run a final check on voltages and the plan before ordering.

He decided on 24V panels with 45.4Voc!!!

Multiply that x 5 panels in Series x 1.1 for temp compensation but I think it gets a lot colder than 36° in 29 Palms.

You use Voc NOT Vmp for max volts input!!! 45.4VocEven the 24v panels should work:

Vmp of 37.6 times 5 = 188v (way below the 250v)

The 250/70 SCC will handle 2000 watts - so what math is incorrect?

You and the other dude are making that same mistake.

Yeah you don't know the difference between Voc and Vmp and acting like a smart ass but really a dumb ass.

You advised dumping 227V into a 150V max input SCC and also did not account for low temps that would increase the Voc to about 250V.

250V into a 150V max SCC is magic smoke time you dumb ass. Lol

If that's the best you can do then stop giving advice.

Yes I "plan" to get the 24v panels, unless I should get 12v. But, I thought you said doing the 10 panels in a 2s5p the 250/70 would work? Am I missing something? Or is that still good? Sorry, just a lot of information coming from different people to some one how is just learning this stuff lol.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,497

Yes I "plan" to get the 24v panels, unless I should get 12v. But, I thought you said doing the 10 panels in a 2s5p the 250/70 would work? Am I missing something? Or is that still good? Sorry, just a lot of information coming from different people to some one how is just learning this stuff lol.

Can you fit 12 panels? Many more ways to factor 12 into series/parallel.

Highest series voltage you can do while never exceeding SCC specs on a record cold day is generally best - lower current in wire from PV to SCC, less loss. Or cheaper, smaller gauge wire.

24V (or 36V) panels generally preferred - used for commercial applications and available very cheap.

Several brands of SCC supporting 150V, 200V, 250V. However, the higher voltage models aren't necessarily the best deal. They often cost more dollars per watt delivered. Select panels and inverter, and calculate what combo works together and fits your available space. (Since panels vary is size and aspect ratio, some models may fill the space better.)

Who said? Who is you?Yes I "plan" to get the 24v panels, unless I should get 12v. But, I thought you said doing the 10 panels in a 2s5p the 250/70 would work? Am I missing something? Or is that still good? Sorry, just a lot of information coming from different people to some one how is just learning this stuff lol.

They were talking about 5S2P on a 250 / 70.

2S5P is absolutely No problem on a 150 / 70. Only 90V!!!

Why get a 250V Victron if you are Only wiring it 2S??????

I never said that and if you are listening to the other dude then good luck!

45.4Voc x 5 = what?

Then allow for cold temps by multiplying by 1.1 or maybe 1.2 if you are realistic about desert temps.

Yes, lower temps than 75°f increase the Voc.

Learn to do the simple math yourself and don't rely on random dudes online.

You are making me work way too hard here and if you smoke your expensive 250 / 70 Victron I won't be crying.

I can only fit 8 to 10 (10 depending on the front support where it starts to curve just slightly on the front of my 5th wheel). I'm still researching and learning. Nothing bought yet except the wire for the panels, wire and BMS's for the batteries, batteries (because they will take months from China) and the strut bars (so i could get them coated).Can you fit 12 panels? Many more ways to factor 12 into series/parallel.

Highest series voltage you can do while never exceeding SCC specs on a record cold day is generally best - lower current in wire from PV to SCC, less loss. Or cheaper, smaller gauge wire.

24V (or 36V) panels generally preferred - used for commercial applications and available very cheap.

Several brands of SCC supporting 150V, 200V, 250V. However, the higher voltage models aren't necessarily the best deal. They often cost more dollars per watt delivered. Select panels and inverter, and calculate what combo works together and fits your available space. (Since panels vary is size and aspect ratio, some models may fill the space better.)

The only reason I'm "maybe planning" on getting the bigger one, is if we take all this out of the RV and put it in our home once we build one. We would have more rooms to place more panels, so figured get the stuff that can handle more for the future. That way we aren't buying a completely new system once we decide to settle.

Lol, sorry, when you retaliate to them (the dudes), you use a lot of sarcasm and it's hard to read over text. I plan, plans change, to do 2s5p with 10 24v panels. The arguing amongst each other is funny, but confusing to some one still learning, meaning me. I'll do the math and figure out what works best for us in our RV. Thank you for all your help, it truly is appreciated.Who said? Who is you?

They were talking about 5S2P on a 250 / 70.

2S5P is absolutely No problem on a 150 / 70. Only 90V!!!

Why get a 250V Victron if you are Only wiring it 2S??????

I never said that and if you are listening to the other dude then good luck!

45.4Voc x 5 = what?

Then allow for cold temps by multiplying by 1.1 or maybe 1.2 if you are realistic about desert temps.

Yes, lower temps than 75°f increase the Voc.

Learn to do the simple math yourself and don't rely on random dudes online.

You are making me work way too hard here and if you smoke your expensive 250 / 70 Victron I won't be crying.

If 20 panels - Get the 12v panels - the 24v panels on a cold crisp morning could fry the 250/70. (I was using the wrong voltage when I calculated it earlier).

When you look at the spec chart on the panels - look for the highest voltage. Each model of panel can/will be different. In the panel on the first page of this thread it has a Voc of 45.4. Times 5 is 227v. Solar panels get more efficient and produce more voltage when they are cold. This could drive the voltage above the 250v.

Options:

Go 4s on those 24v panels

Find some 24v panels that have a little lower Voc (Probably about 40)

Go 5s on some 12v panels

Go with a 3s3p arrangement

I just looked at the 12v 200w panels I installed on my rig (Hightec Solar)

Voc of 24.33

Amp of just under 10

So in a 5s2p there would be 20amps down to the SCC - Did you say you a had a 10ga wire to the SCC? If so that would be fine. You could use the SCC 150/70 in that case.

Really it all depends on the voltages of the panel you choose.

When you look at the spec chart on the panels - look for the highest voltage. Each model of panel can/will be different. In the panel on the first page of this thread it has a Voc of 45.4. Times 5 is 227v. Solar panels get more efficient and produce more voltage when they are cold. This could drive the voltage above the 250v.

Options:

Go 4s on those 24v panels

Find some 24v panels that have a little lower Voc (Probably about 40)

Go 5s on some 12v panels

Go with a 3s3p arrangement

I just looked at the 12v 200w panels I installed on my rig (Hightec Solar)

Voc of 24.33

Amp of just under 10

So in a 5s2p there would be 20amps down to the SCC - Did you say you a had a 10ga wire to the SCC? If so that would be fine. You could use the SCC 150/70 in that case.

Really it all depends on the voltages of the panel you choose.

Jesus you are a real cheeky smart arse arn't you . Whats got up your nose . Nobody else entitled to an opinion , right or wrong.? Ever heard of a MOV , fitted to all the modern stuff . Most can take the occassional overvoltage prune.Yeah you don't know the difference between Voc and Vmp and acting like a smart ass but really a dumb ass.

You advised dumping 227V into a 150V max input SCC and also did not account for low temps that would increase the Voc to about 250V.

250V into a 150V max SCC is magic smoke time you dumb ass. Lol

If that's the best you can do then stop giving advice.

You are hogging the thread somewhat . Whether you think you are right or wrong ,how about giving it a break?

TankFish do the 250/100 charger and use 5s2p . It will rarely exceed that if ever.

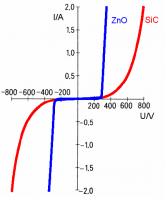

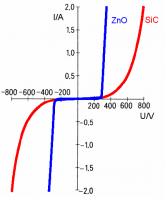

Voc is when there is no load at all -open circuit. You will always have a load connected Use Voc a 3.5% if you are a cautious prude. Use Vmp if you are a practical doityourselfer.

Voltage at maximum power (Vmp)

The voltage at maximum power is the voltage when the power output is the greatest. It is the actual voltage you want to see when it is connected to the MPPT controller under standard test conditions. In practice the actual Vmp will vary during course of a day and with temperature, shading, soiling of the panel surface, etc. You can measure this voltage with a multimeter at the solar input terminals of an MPPT controller during bulk-charge mode.

Last edited:

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,497

Here are MOVs

www.digikey.com

www.digikey.com

Can you suggest one that would protect a 150V SCC input when PV string of excessive Voc is connected?

(It needs to dissipate the power it sees from clamping voltage to safe level.)

Circuit Protection | TVS - Varistors, MOVs | DigiKey

Circuit Protection - TVS - Varistors, MOVs are in stock at Digikey. Order Now! Circuit Protection ship same day

Can you suggest one that would protect a 150V SCC input when PV string of excessive Voc is connected?

(It needs to dissipate the power it sees from clamping voltage to safe level.)

Check out the victron site . I could be wrong but I run mine on the understanding that overvoltage from the PV is simply ignored and not passed .I've been running one for 3 years plus now and it does occassionally top out on some of the blazingly hot days we have here but it sheds the overvoltage to ground and I don't see any other device responsible in the circuit.Question on MOV's

The plus side is on our many rainy cloudy days my cells are recharged in the first few daylight hours.

Clearly up over 185 volts is pushing it so the 250 volt model would be a safer course and its only an extra $100 so why not and save that on branch Y connectors and smaller wire .

Last edited:

EricBarbour

meh

jeez............just wire the panels 2S5P and you (and the charge controller) will be fine.

One set of these 1-to-5 branch connectors will do it. It even includes 10 spare MC4 connectors for spares or other uses.

One set of these 1-to-5 branch connectors will do it. It even includes 10 spare MC4 connectors for spares or other uses.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,497

Check out the victron site . I could be wrong but I run mine on the understanding that overvoltage from the PV is simply ignored and not passed .I've been running one for 3 years plus now and it does occassionally top out on some of the blazingly hot days we have here but it sheds the overvoltage to ground and I don't see any other device responsible in the circuit.

The plus side is on our many rainy cloudy days my cells are recharged in the first few daylight hours.

Clearly up over 185 volts is pushing it so the 250 volt model would be a safer course and its only an extra $100 so why not and save that on branch Y connectors and smaller wire .

Victron may handle that, and some Midnight have "Hyper VoC" to handle it as well.

If VoC slightly exceeds limit, a FET with suitable Vds spec could open-circuit the PV input, so capacitors don't get charged to high. Array would remain at Voc with no load until they warmed up.

That would let designer not worry about record cold. Reasonable cold, if Voc remained too high, would mean inverter never connects to PV and no charging occurs. e.g. 185 Voc for a 150V SCC, 35V or 23% over. Temperature would have to rise 78 degrees (assuming 0.3%/degree) before SCC could connect; that's a non-starter.

I've thought about how to support higher Voc strings. Pulling voltage down to an acceptable level can involve a huge amount of power to be dissipated, which is why I challenged you to show how a MOV could be used. They are good for eating momentary spikes carrying a limited number of Joules. While MOV could be used as a trigger circuit (if its voltage was more tightly controlled than I see in data sheets), something else would have to clamp or open the circuit.

As you say, selecting SCC specs to match PV array configuration is the way to go.

But a MOV does not operate like that . It holds a very high resistance until its threshold is crossed and then the resistance begins to drop allowing current to flow to ground increasing as the voltage increases and reducing as voltage reduces . Its not a switch to turn another mosfet on . Its a gradual dumping of more and more current as voltage increases and is connected directly across positive and negative lines.I've thought about how to support higher Voc strings. Pulling voltage down to an acceptable level can involve a huge amount of power to be dissipated, which is why I challenged you to show how a MOV could be used. They are good for eating momentary spikes carrying a limited number of Joules. While MOV could be used as a trigger circuit (if its voltage was more tightly controlled than I see in data sheets), something else would have to clamp or open the circuit.

At least that's how I use them.

Even the cheap solar controllers today usually have one . Too high a voltage for too long and it will fuse on as a direct short and must be removed before the solar controller will work again. A lightening strike for instance will fuse it shorted usually.

Last edited:

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,497

Yes, MOV has a knee in the curve, voltage above which it conducts a considerable amount of current so it clamps source to desired voltage. That means it dissipates power equal to clamping voltage times current required to pull source down to that voltage.

In the event of ESD, inductive transient, coupled current from nearby lightning, it turns the short pulse into heat, which then dissipates over time to air.

Values like 120 joules (amps x seconds x volts). This one is 240V 10,000A peak, could take that for 50 microseconds:

www.digikey.com

www.digikey.com

It will eat the energy of a brief transient and survive for another. If too much energy it shorts out (probably then burns up, not sure it can clamp a source like PV to low enough voltage to not overheat further.)

MOV couldn't be used to protect against over-voltage from PV.

A different circuit is needed for that.

In the event of ESD, inductive transient, coupled current from nearby lightning, it turns the short pulse into heat, which then dissipates over time to air.

Values like 120 joules (amps x seconds x volts). This one is 240V 10,000A peak, could take that for 50 microseconds:

TMOV20RP150E Littelfuse Inc. | Circuit Protection | DigiKey

Order today, ships today. TMOV20RP150E – 240 V 10 kA Varistor 1 Circuit Through Hole Disc 20mm from Littelfuse Inc.. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

It will eat the energy of a brief transient and survive for another. If too much energy it shorts out (probably then burns up, not sure it can clamp a source like PV to low enough voltage to not overheat further.)

MOV couldn't be used to protect against over-voltage from PV.

A different circuit is needed for that.

RV50A IS SPLIT PHASEI have a 50amp RV so not split phase but 2x120v separate connections. I'll be running 1 MultiPlus to each individual 120v line.

I was looking at the GX, but I didn't quite understand how it all linked, so I strayed away. I was trying to find a good video, but most of the videos I found that showed operating and installing were people flying through stuff and speaking "doctor".

If you do not have ANY 240V loads, it doesn’t have to be, but it is a split phase connection and panel.

be aware, that some RV wiring uses multiwire shared neutral... so a split phase setup is wise if you do not know how the RV is wired...

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,497

RV50A IS SPLIT PHASE

If you do not have ANY 240V loads, it doesn’t have to be, but it is a split phase connection and panel.

be aware, that some RV wiring uses multiwire shared neutral... so a split phase setup is wise if you do not know how the RV is wired...

Come to think of it, I [think] RV are normally wired so circuits on both halves of breaker panel can be on same 120V phase. This requires they not share white neutral, to avoid adding current in it.

"some RV wiring uses multiwire shared neutral"

Meaning two 20A 120V circuits, if fed with same phase, would have 40A in their shared neutral?

Common shore power cord is 50A 120/240V. It can be adapted to 30A 120V, in which case about 30A is maximum continuous that could be put through any neutral in the RV. Since a 30A breaker can carry 45A for 10 to 20 minutes, that's really to much for 12awg.

Back to that power cord: Designed for 50A, it counts on the neutral of the power cord carrying difference between two hots, not sum.

If TankFish uses two unsynchronized 120V sources, should either bypass the 50A cord or ensure sum of two sources in parallel doesn't exceed 50A.

Feeding a single 120V into both hots of a circuit with a 240V load should be OK because that load would see zero.

Feeding two unsynchronized 120V into the two separate hots would not be OK; the 240V load would see variable zero to 240V.

A 50A shore power rv outlet can be connected with a 30A adapter, but I do not think a 30A shore power outlet can be adapted to a 50A RV.Come to think of it, I [think] RV are normally wired so circuits on both halves of breaker panel can be on same 120V phase. This requires they not share white neutral, to avoid adding current in it.

"some RV wiring uses multiwire shared neutral"

Meaning two 20A 120V circuits, if fed with same phase, would have 40A in their shared neutral?

Common shore power cord is 50A 120/240V. It can be adapted to 30A 120V, in which case about 30A is maximum continuous that could be put through any neutral in the RV. Since a 30A breaker can carry 45A for 10 to 20 minutes, that's really to much for 12awg.

However... I am not an RV electrician.

I have built many RV shore outlets though.

240V appliances are often used in RV’s with 50A cords... and multiwire circuits are also frequently used to save wire weight.

As long as no 2 pole breakers are in the panel, feeding 120V should be fine... but the chance exists where an over current neutral is present.

Last edited:

Similar threads

- Replies

- 2

- Views

- 270

- Replies

- 6

- Views

- 445