brandnewb

Going for serious. starting as newb

cool video. I am not understanding it yet though. Anyway I am not going to use ferrite as this is not a high frequency applicaiton. I am going to use iron powder.

www.amidoncorp.com

www.amidoncorp.com

I am not sure how to measure that. I've spend an hour or so reading up and searching and found nothing I understand or I find only things that seem inconsistent.What is the magnetic permeability of the powder?

I really prefer to learn how to make my own transformers as I will be needing more in the future that are highly specific to a custom scenario and therefore simply not (easily) store bought.Or you could just let someone with one or two dc power supplies do the test safely. My two will only go up to 80A at 3.6VDC

Yes you are right. The torodial transformer you saw on the picture can have 110 or 220VAC input. Currently the primary coils are connected in series as to allow for an 220VAC input.two coils might be connected in series

Yes indeed. The primary coil is still original. The original secondary I already removed and wound my ownWithout anything connected to toroid transformer, measuring voltage in and out gives ratio of turns.

I'll try and wrap my head around that.The variacs I've seen go some percentage above input voltage. Yours has a meter up to 300V. 25% would be 75V from variac into toroid. You haven't indicated what voltage ratio toroid has. Open-circuit, that is. "150 mV" is its output pulled down with the short circuit loading it.

great, that might yield some useful data.Measured with/without core material should give an indication of relative permeability.

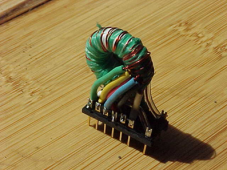

Yes you might well be correct. I tried my best but I can already see some powder leaking out and it was never 100% filled to begin with.Without a plumbing "T" to fill from, I would imagine there are airgaps without powder. But that probably isn't the biggest problem, rather the relative permeability being low.

it's calledIs your iron powder intended for making magnets, or for sintering to use in other applications?

yes sir, sometimes I make costly mistakes ;(Could have left it intact and just added your own winding.

that makes all of us I am afraid. But wi'll find out.It is attracted to a magnet, but I have no idea how it will serve as core for an AC circuit

I tried hooking up a spool of 1mm enameld wire directly to the variac. (That is alot of winds running about 70 meters) At 4VAC the variac begins grouwling and I do not dare to take it any further.Very little current is required to drive a coil to saturation

I tried hooking up a spool of 1mm enameld wire directly to the variac. (That is alot of winds running about 70 meters) At 4VAC the variac begins grouwling and I do not dare to take it any further.

Is this because the coil is saturated? and adding a core of some kind will increase it's 'range'?

It does seem that having many winds will reduce the likeliness that the circuit breaker will trip.

Variac → isolation transformer (220 → 12) → +- 290 turns 1mm coil | | | |

| | | |

no iron core | amp in variac | amp in coil | VAC in coil |

variac setting (V) | | | |

0 | 0.122 | <0.1 | 0 |

50 | 0.114 | 0.3 | 0.53 |

100 | 0.13 | 0.5 | 1.02 |

150 | 0.16 | 0.8 | 1.48 |

200 | 0.172 | 1 | 1.82 |

max | 0.195 | 1.2 | 2.21 |

| | | |

iron core (+-750g) | amp in variac | amp in coil | VAC in coil |

variac setting (V) | | | |

0 | 0.102 | <0.1 | 0 |

50 | 0.105 | 0.3 | 0.73 |

100 | 0.122 | 0.5 | 1.44 |

150 | 0.145 | 0.8 | 2.04 |

200 | 0.167 | 1 | 2.62 |

max | 0.193 | 1.2 | 3.22 |