Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,508

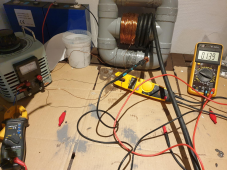

For strong enough field, you can use a pickup coil and read AC volts.

One guy at work has a hand-held meter he uses to check magnetic field around transformers.

At low AC voltage, coil around core is an inductor. V = L x di/dt, or V = I x j w L (where "w" is a stand-in for omega = 2 pi f)

That gives linear Irms / Vrms ratio.

Above saturation, response takes on the V = I x R, where R is winding resistance.

As you turn up Variac, current shoots up and is hard to control.

Put a resistor or light bulb in series with variac (or with step-down transformer). That will let you turn knob more smoothly and control current to what you want. Then record voltage and current (two or more significant digits) and graph. If clamp ammeter doesn't have good enough resolution, use 10 turns of wire to scale reading 10x.

I just used the resistor for that purpose at work. My choke was 0.040 ohms DC, an I used a 4.0 ohm power resistor.

One guy at work has a hand-held meter he uses to check magnetic field around transformers.

At low AC voltage, coil around core is an inductor. V = L x di/dt, or V = I x j w L (where "w" is a stand-in for omega = 2 pi f)

That gives linear Irms / Vrms ratio.

Above saturation, response takes on the V = I x R, where R is winding resistance.

As you turn up Variac, current shoots up and is hard to control.

Put a resistor or light bulb in series with variac (or with step-down transformer). That will let you turn knob more smoothly and control current to what you want. Then record voltage and current (two or more significant digits) and graph. If clamp ammeter doesn't have good enough resolution, use 10 turns of wire to scale reading 10x.

I just used the resistor for that purpose at work. My choke was 0.040 ohms DC, an I used a 4.0 ohm power resistor.