Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

Introduction:

I posted this into a response and felt that this should have its own thread as a point of clarification. There has been much debate, discusion and even theories, conjecture & postulation. All of this creates confusion due to many perceived points, real or otherwise. This is by no means the full and final word on the matter but rather more of an anchor in an unsteady sea. Some may disagree and that is perfectly fine. These are based on observations in real & practical use & application including some fairly extreme testing & even abusing of LFP (LiFePO4) cells. I will likely post a detailed thread about the Thrash Test Process I have been doing, warning that it's not for the light of heart as that progresses.

The figures represented are "General" averages. Always refer to the Manufacturers Specification Datasheet for the Cells you are working with. NEVER Assume they are all the same, they are NOT ! Even between different models from the same Manufacturer IE: Calb CA, CAM & SE models are LFP but very different.

I am sorry but this is more "to the point" bullet type points. Let me put this as plainly, clearly & simply as possible, as translation issues are considered. Some translation software can be overly creative shall we say. We have all suffered that so.

NONE of the EVE, Lishen or other brands of cells being sold as "Storage" or "ESS" or anything like that at these price points are MATCHED or even BATCHED.

NONE !

Vendors sort them by Voltage (typically 2.99 to 3.20 voltage - storage & shipping voltage) so that matches up. Then they double-check with a YR1030 or YR1035 to see if the standing IR (Internal Resistance) is the same. They in turn CALL THAT MATCHED ! In one sense, this is correct BUT it is misleading in the grand scheme of things, it is a play on Interpretation. BE AWARE OF THIS, you have been duly warned.

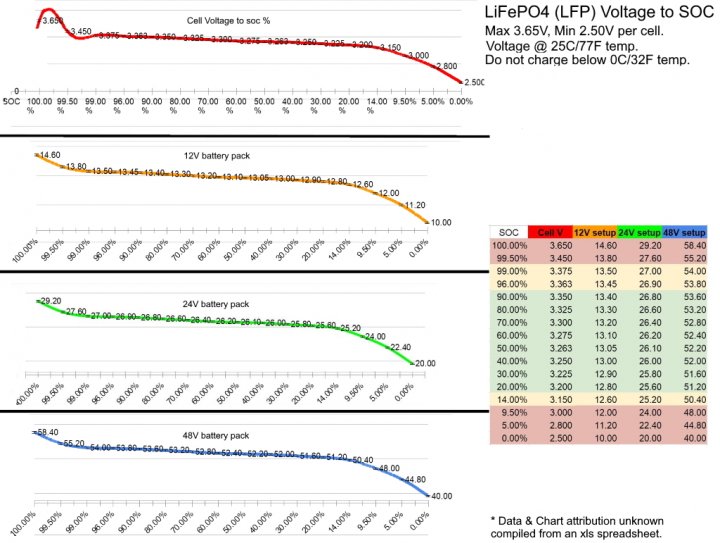

They will NOT match up during Charge or Discharge. They will deviate above 3.40V and below 3.10V without manually conditioning the cells by Bottom & Top Balancing. Top Balancing CAN improve the top side some but not the low side. This is also a very marginal gain related to the voltage curve.

You will get "RUNNERS". These are cells with variable IR. They will either RUN to 2.50V Fast from around 3.10V while the others are above 3.1V or RUN to 3.65V from 3.40V while the others are still at 3.850 and above. These Runners LIMIT the total battery pack capacity as they will force Low Volt Disconnect (LVD) or High Volt Disconnect (HVD) cutoff before the other cells reach that point. These are runners because they transition FAST. The "Runners" appear to be roughly 10% of cells sold. * Runners can be batched together (as a pack) if they match Top & Bottom giving a reasonable return, but it will be the "oddball" with tricky edges.

280AH cells can deviate as much as 280mv, or 1mv per AH capacity, either at the top or bottom. This seems to hold true to other sizes as well.

Manual Conditioning & preparation is ESSENTIAL for these COMMODITY CELLS. That is Bottom & Top Balancing.

Failure to do so, will not realize the full potential of the assembly.

* Nota Bene * This will also result in havoc with SOC reading accuracy if not done.

Premium EV Grade, Grade-A Cells will cost 2X just to start PLUS the cost of Matching & Batching which can easily add $50+ per cell to the cost.

Fortunately: LFP optimal voltage is 3.2V per cell. The cells "as is" function well between 3.180 to 3.400 +/-. This is actually the primary curve for the chemistry.

- Below 3.00V is pointless, it is the end of the curve and only represents <5% of the AH Capacity.

- Above 3.50V is also only about 5% of actual capacity, Charge LFP to 3.65V till amps taken = 1A, within an hour the cell will settle between 3.55 to 3.50, this is NORMAL and not unexpected.

- Most folks, to ensure Long Lifespan & Cycle Life generally reserve off the top above 3.5 and below 3.0 anyways.

The ONLY way to verify IR and to manually test, sort & batch them is a process. An IR Tester such as this (the OEM, not a relabelled VAR) Real Four Wire Lithium Battery Internal Resistance Tester YR1035+ Nickel Hydrogen Lead Button Polymer Alkalinity|Battery Testers| - AliExpress is required. * Also available on EBay/Amazon, beware of knock offs, many are rebranded by VARS (value added resellers), Yoarea IS the OEM. (original equipment manufacturer)

Pre-Balancing Cells | Orion Li-Ion Battery Management System

High resistance cell | Orion Li-Ion Battery Management System

AN FYI EXAMPLE: Custom Job for matching cells (batteryspace.com) It is not a joke ! Matching & Batching = $$ due to time & resources required. Gear for doing large batches cost as much as a house !

When discharging/charging cells for top/bottom balancing and after assembly, remember to "FIX" or "Clamp" the cells together. They will expand & contract up to 2mm per cell (normal) during their cycles. You do not want them to Puff or Bloat. REFER TO MANUFACTURER SPEC SHEET ! Typical recommendation is 12psi @ 50% SOC

When discharging/charging cells for top/bottom balancing and after assembly, remember to "FIX" or "Clamp" the cells together. They will expand & contract up to 2mm per cell (normal) during their cycles. You do not want them to Puff or Bloat. REFER TO MANUFACTURER SPEC SHEET ! Typical recommendation is 12psi @ 50% SOC

TIGHTENING TORQUES:

- 70 kgf.cm (5.0 lbf.ft)

- 35 kgf.cm (2.5 lbf.ft)

- 7 to 12 kgf.cm (0.5 to 0.9 lbf.ft)

Preparation, the Devil in the Details:

Ensure that Cell Contact surfaces are clean of greases, waxes & oils (there is often cutting oil from tapping cells and waxes to protect from corrosion.

Also, clean your BusBars regardless of type, again Oils & Waxes can cause issues with readings.

GUARANTEE that there are no Burrs, Ridges or Edges on the busbars. The stamped ones all have a slight ridge. Made ones always have burrs.

-- File the ridges down or chamfer the holes slightly which is better.

You can use a very small amount of NoAlox/OxGuard on the cell contact surface to reduce corrosion potential. DO NOT GET ON THREADS ! It is a grease and will seriously affect PSI readings when tightening bolts. Stripping the thread = BAD.

NOTE, the above oils, waxes, ridges can and do affect readings, and can cause IR issues where cells posts will heat up due to poor contact. They can also create other side effects which are not immediately observable.

When Companies are Calculating the WH Rating of cells they use 3.20V which is the Nominal Voltage.

The Formula, 24V example: 3.2V X 8cells X 100AH = 2560 WH

Hope this helps, Good Luck.

Steve

IF WARRANTED, I would be willing to collaborate on an addendum related to doing Self Matching Cells. There are many "partial pieces" floating around on the forum and that should likely be compiled into one digestible "to the point" reference. That is presently beyond the scope of this particular thread.

Please, let us keep this ON TOPIC without side trips or hijacking. I do not want to be mean but once threads get cluttered with irrelevant meanderings they end up being near useless.

Thank You in Advance for your cooperation.

I posted this into a response and felt that this should have its own thread as a point of clarification. There has been much debate, discusion and even theories, conjecture & postulation. All of this creates confusion due to many perceived points, real or otherwise. This is by no means the full and final word on the matter but rather more of an anchor in an unsteady sea. Some may disagree and that is perfectly fine. These are based on observations in real & practical use & application including some fairly extreme testing & even abusing of LFP (LiFePO4) cells. I will likely post a detailed thread about the Thrash Test Process I have been doing, warning that it's not for the light of heart as that progresses.

The figures represented are "General" averages. Always refer to the Manufacturers Specification Datasheet for the Cells you are working with. NEVER Assume they are all the same, they are NOT ! Even between different models from the same Manufacturer IE: Calb CA, CAM & SE models are LFP but very different.

I am sorry but this is more "to the point" bullet type points. Let me put this as plainly, clearly & simply as possible, as translation issues are considered. Some translation software can be overly creative shall we say. We have all suffered that so.

NONE of the EVE, Lishen or other brands of cells being sold as "Storage" or "ESS" or anything like that at these price points are MATCHED or even BATCHED.

NONE !

Vendors sort them by Voltage (typically 2.99 to 3.20 voltage - storage & shipping voltage) so that matches up. Then they double-check with a YR1030 or YR1035 to see if the standing IR (Internal Resistance) is the same. They in turn CALL THAT MATCHED ! In one sense, this is correct BUT it is misleading in the grand scheme of things, it is a play on Interpretation. BE AWARE OF THIS, you have been duly warned.

They will NOT match up during Charge or Discharge. They will deviate above 3.40V and below 3.10V without manually conditioning the cells by Bottom & Top Balancing. Top Balancing CAN improve the top side some but not the low side. This is also a very marginal gain related to the voltage curve.

You will get "RUNNERS". These are cells with variable IR. They will either RUN to 2.50V Fast from around 3.10V while the others are above 3.1V or RUN to 3.65V from 3.40V while the others are still at 3.850 and above. These Runners LIMIT the total battery pack capacity as they will force Low Volt Disconnect (LVD) or High Volt Disconnect (HVD) cutoff before the other cells reach that point. These are runners because they transition FAST. The "Runners" appear to be roughly 10% of cells sold. * Runners can be batched together (as a pack) if they match Top & Bottom giving a reasonable return, but it will be the "oddball" with tricky edges.

280AH cells can deviate as much as 280mv, or 1mv per AH capacity, either at the top or bottom. This seems to hold true to other sizes as well.

Manual Conditioning & preparation is ESSENTIAL for these COMMODITY CELLS. That is Bottom & Top Balancing.

Failure to do so, will not realize the full potential of the assembly.

* Nota Bene * This will also result in havoc with SOC reading accuracy if not done.

Premium EV Grade, Grade-A Cells will cost 2X just to start PLUS the cost of Matching & Batching which can easily add $50+ per cell to the cost.

Fortunately: LFP optimal voltage is 3.2V per cell. The cells "as is" function well between 3.180 to 3.400 +/-. This is actually the primary curve for the chemistry.

- Below 3.00V is pointless, it is the end of the curve and only represents <5% of the AH Capacity.

- Above 3.50V is also only about 5% of actual capacity, Charge LFP to 3.65V till amps taken = 1A, within an hour the cell will settle between 3.55 to 3.50, this is NORMAL and not unexpected.

- Most folks, to ensure Long Lifespan & Cycle Life generally reserve off the top above 3.5 and below 3.0 anyways.

The ONLY way to verify IR and to manually test, sort & batch them is a process. An IR Tester such as this (the OEM, not a relabelled VAR) Real Four Wire Lithium Battery Internal Resistance Tester YR1035+ Nickel Hydrogen Lead Button Polymer Alkalinity|Battery Testers| - AliExpress is required. * Also available on EBay/Amazon, beware of knock offs, many are rebranded by VARS (value added resellers), Yoarea IS the OEM. (original equipment manufacturer)

Pre-Balancing Cells | Orion Li-Ion Battery Management System

High resistance cell | Orion Li-Ion Battery Management System

AN FYI EXAMPLE: Custom Job for matching cells (batteryspace.com) It is not a joke ! Matching & Batching = $$ due to time & resources required. Gear for doing large batches cost as much as a house !

TIGHTENING TORQUES:

- 70 kgf.cm (5.0 lbf.ft)

- 35 kgf.cm (2.5 lbf.ft)

- 7 to 12 kgf.cm (0.5 to 0.9 lbf.ft)

Preparation, the Devil in the Details:

Ensure that Cell Contact surfaces are clean of greases, waxes & oils (there is often cutting oil from tapping cells and waxes to protect from corrosion.

Also, clean your BusBars regardless of type, again Oils & Waxes can cause issues with readings.

GUARANTEE that there are no Burrs, Ridges or Edges on the busbars. The stamped ones all have a slight ridge. Made ones always have burrs.

-- File the ridges down or chamfer the holes slightly which is better.

You can use a very small amount of NoAlox/OxGuard on the cell contact surface to reduce corrosion potential. DO NOT GET ON THREADS ! It is a grease and will seriously affect PSI readings when tightening bolts. Stripping the thread = BAD.

NOTE, the above oils, waxes, ridges can and do affect readings, and can cause IR issues where cells posts will heat up due to poor contact. They can also create other side effects which are not immediately observable.

When Companies are Calculating the WH Rating of cells they use 3.20V which is the Nominal Voltage.

The Formula, 24V example: 3.2V X 8cells X 100AH = 2560 WH

Hope this helps, Good Luck.

Steve

IF WARRANTED, I would be willing to collaborate on an addendum related to doing Self Matching Cells. There are many "partial pieces" floating around on the forum and that should likely be compiled into one digestible "to the point" reference. That is presently beyond the scope of this particular thread.

Please, let us keep this ON TOPIC without side trips or hijacking. I do not want to be mean but once threads get cluttered with irrelevant meanderings they end up being near useless.

Thank You in Advance for your cooperation.

Last edited: