Sverige

A Brit in Sweden

I thought I’d record the process I have recently followed to improve the performance of a couple of lead acid car batteries which I’ve been using in my off grid set up. Unfortunately I didn’t measured the capacity or internal resistance of the batteries before and after, but I can see that my efforts have been successful because the self discharge of the batteries is much reduced now.

On each battery I applied 15.3V from a server PSU with max 45A current supply capacity, while monitoring current drawn. Beginning with just a few minutes of this 15.3V treatment I alternated with using a proper “off the shelf” car battery charger of around 14V for longer. So in other words the battery was taking a short burst of 15.3V high current, then a longer trickle charge at lower voltage.

At the start of this, both batteries were absorbing just under 20A at the higher voltage, but this current declined as the charge progressed. After something like 3 hours overall, most of which time was at the lower 14V, the batteries were accepting under 2A when connected to the higher volt PSU.

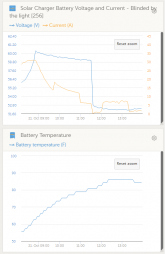

The effect on the battery performance of this equalisation has been quite marked, as both batteries now maintain their voltage overnight, even when a small load of 1-2A is being drawn. Previously they would sink from 12.4V down to 11.9 or 11.8 overnight, even with the lightest of loads, so self-discharge was excessive.

Now someone will perhaps tell me I’ve taken a terrible risk and my SLA batteries might have exploded, but I hope not to have to repeat this procedure anyway and the benefits seem worthy of a mention. The batteries were around 10C because of the generally low ambient temps at this time of year where I am. I didn’t notice any increase in their temp during the charging, but in a warmer climate this would of course be something to be monitored more closely.

On each battery I applied 15.3V from a server PSU with max 45A current supply capacity, while monitoring current drawn. Beginning with just a few minutes of this 15.3V treatment I alternated with using a proper “off the shelf” car battery charger of around 14V for longer. So in other words the battery was taking a short burst of 15.3V high current, then a longer trickle charge at lower voltage.

At the start of this, both batteries were absorbing just under 20A at the higher voltage, but this current declined as the charge progressed. After something like 3 hours overall, most of which time was at the lower 14V, the batteries were accepting under 2A when connected to the higher volt PSU.

The effect on the battery performance of this equalisation has been quite marked, as both batteries now maintain their voltage overnight, even when a small load of 1-2A is being drawn. Previously they would sink from 12.4V down to 11.9 or 11.8 overnight, even with the lightest of loads, so self-discharge was excessive.

Now someone will perhaps tell me I’ve taken a terrible risk and my SLA batteries might have exploded, but I hope not to have to repeat this procedure anyway and the benefits seem worthy of a mention. The batteries were around 10C because of the generally low ambient temps at this time of year where I am. I didn’t notice any increase in their temp during the charging, but in a warmer climate this would of course be something to be monitored more closely.