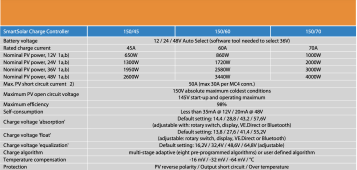

I keep going back and forth between 12V & 24V. The few reasons I go back to 12V:I would seriously look at going 24V for your system. It’s a big system for 12V. Start looking at the amps you will be pulling, and the wiring and fusing it will require. This will help you decide whether 12V is even feasible.

- I really like that the Victron MultiPlus II will do all the switching for me, since I have split phase 50A shore / generator power. However, If I go with 24V, that's not available, and I'd need to get a smart phase selector.

- I really like the idea of 24V allowing for smaller wire sizes, not so much for cost, but because of the reduced current and therefore reduced heat.

- I'd like to be able to charge while I'm driving, and that seems to be much simpler at 12V with the stock alternator.

- I believe availability of 12V solar panels / sizes is better?

- Won't need a 24v to 12v converter for DC loads. Again, not a cost thing, but more of a "one more thing that could fail" thing.

Do you have any other insights that would help steer me in the best direction?