TheGriz

More Power Scottie!!!

- Joined

- Feb 17, 2020

- Messages

- 128

I was all excited about getting my four 280Ah 3.2V prismatic aluminum cells today. Got FedEx text at 5:30am this morning that they were on vehicle for delivery!!! Then an hour ago, I get another text that delivery is rescheduled for tomorrow. Certainly need to exercise extreme patience during these crazy times.

Expertise needed for this noobie please:

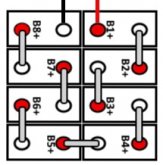

1. From watching Will's vids and others, it looks like I need to "bound" the four cells together. I see different methods: hose clamps which I am not crazy about; using tape of differing varieties. What is the brain trust out there using to bound the cells together?

2. Do I bound all four cells tightly together? Or leave a small gap between each for air circulation?

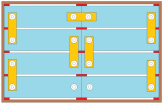

3. Suggestions for case to enclose the four cell pack. I do have some fabrication capabilities/abilities. I am figuring the finished dimensions of the cell pack "Cube" (if bound tightly together) will be roughly 8.5"(H) X 6.85(W)" X 11.36"(L). Height includes the buss bars, and Length presumes four cells bound together with no air space between cells. The case will also need to enclose the Chargery BMS8T and an insulating panel of some sort on top of terminals and buss bars. I am estimating the "pack" to weigh approximately 50 pounds not including whatever the case is going be.

4. Is ventilation needed for the case, and if so how much and how to ventilate?

5. The manufacturer of these cells in EVE Energy. I looked in depth at the 8 page spec sheets. But didn't see any guidance on cell orientation, e.g. Upright, on side, on edge. Any insight on orientation limitations of these cells?

FYI...I am trying to keep this cell pack portable for multiple uses: ham radio field use; RV boondocking; home use during power outage with 2000w/4000w pure sine wave inverter; and who knows what else. Already have a 100w solar panel/SCC for use when needed.

I look forward to this brain trust's insight!!!

Mike

P.S. - Hope all are well out there. Please remember to social distance and self-quarantine where required! We all need to act responsibly for the sake of ourselves, family, friends, and the world.

Expertise needed for this noobie please:

1. From watching Will's vids and others, it looks like I need to "bound" the four cells together. I see different methods: hose clamps which I am not crazy about; using tape of differing varieties. What is the brain trust out there using to bound the cells together?

2. Do I bound all four cells tightly together? Or leave a small gap between each for air circulation?

3. Suggestions for case to enclose the four cell pack. I do have some fabrication capabilities/abilities. I am figuring the finished dimensions of the cell pack "Cube" (if bound tightly together) will be roughly 8.5"(H) X 6.85(W)" X 11.36"(L). Height includes the buss bars, and Length presumes four cells bound together with no air space between cells. The case will also need to enclose the Chargery BMS8T and an insulating panel of some sort on top of terminals and buss bars. I am estimating the "pack" to weigh approximately 50 pounds not including whatever the case is going be.

4. Is ventilation needed for the case, and if so how much and how to ventilate?

5. The manufacturer of these cells in EVE Energy. I looked in depth at the 8 page spec sheets. But didn't see any guidance on cell orientation, e.g. Upright, on side, on edge. Any insight on orientation limitations of these cells?

FYI...I am trying to keep this cell pack portable for multiple uses: ham radio field use; RV boondocking; home use during power outage with 2000w/4000w pure sine wave inverter; and who knows what else. Already have a 100w solar panel/SCC for use when needed.

I look forward to this brain trust's insight!!!

Mike

P.S. - Hope all are well out there. Please remember to social distance and self-quarantine where required! We all need to act responsibly for the sake of ourselves, family, friends, and the world.